How to Deal with the Urban Construction Waste?

Date:2019-04-18Through 40 years of reform and opening up, China has made unprecedented achievements in economic construction. Economic development depends on the hardware environment provided by capital construction. Correspondingly, economic development also provides financial guarantee for capital construction. With the prosperity of the economy, lots of industrial and infrastructure facilities emerge, generating a large amount of construction waste, which also brings about environmental problems such as land occupation, broken soil structure, water pollution, atmosphere pollution and so on.

Today, with the development of industrial technology, construction waste is regarded as the most potential and inexhaustible "urban mineral deposit" and "misplaced local resources". construction waste recycling, reduction and harmlessness is not only the deepening of the understanding of construction waste, but also the inevitable requirement of urban development.

Prospects of recycling and reusing construction waste

After sorting, removing or crushing, many wastes in construction waste can be reused as renewable resources, such as scrap steel bar, scrap iron wire, scrap wire and other metals. After sorting, centralizing and refining, they can be processed into various specifications of steel; scrap bamboo wood can be used to make artificial wood; brick, stone, concrete and other wastes after crushing can replace sand, be used for masonry mortar and concrete cushion, and can also be used to make blocks, paving bricks, Plaid bricks and other building materials products.

Vanguard Machinery Construction Waste Disposal Solution:

Stationary construction waste crushing plant

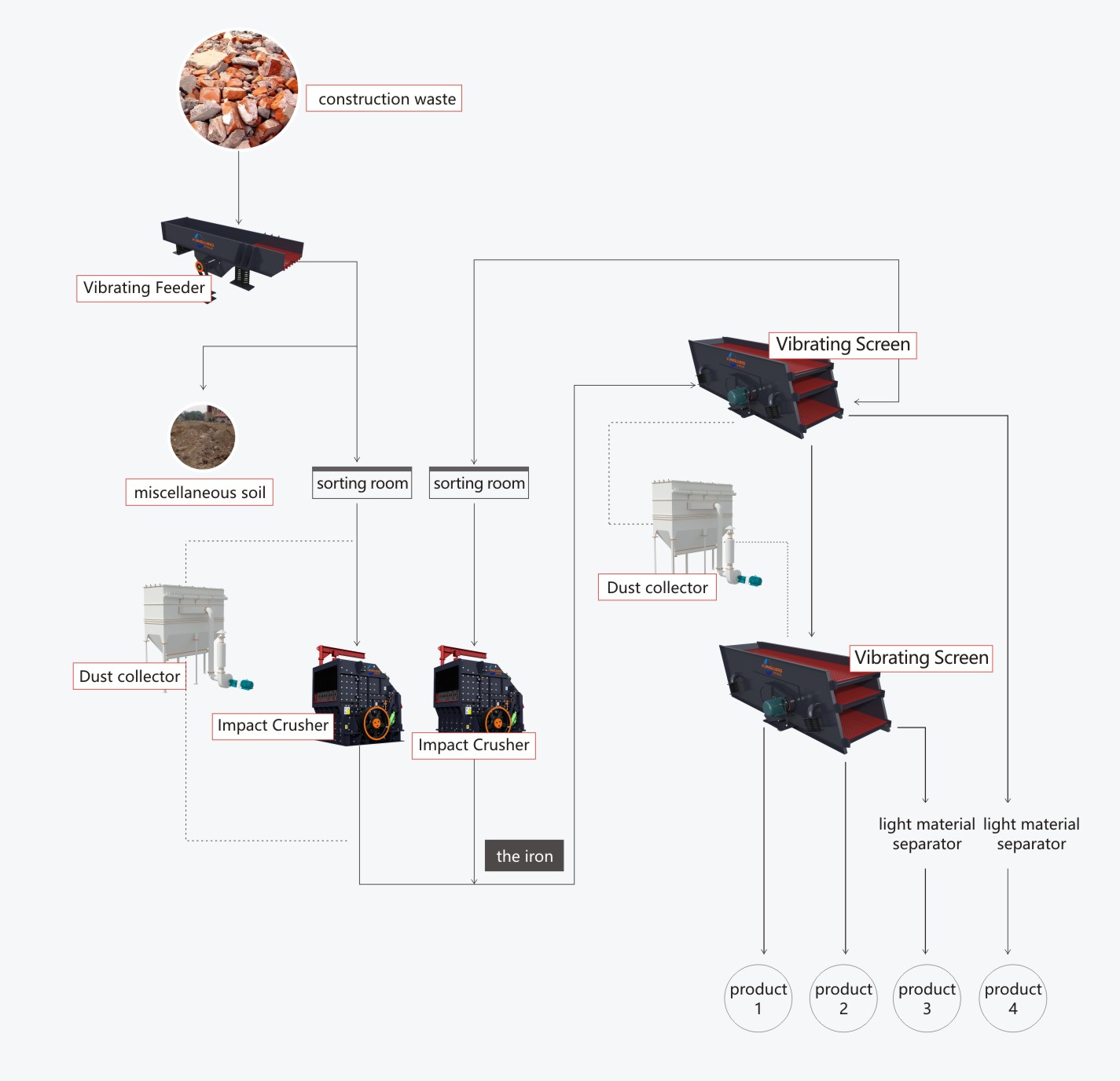

Stationary construction waste treatment production line is composed of crusher, screen, silo, feeder, conveyor, ventilation and dust removal equipment and control system. Due to different raw material conditions and product requirements, different combinations can be made to meet different process requirements and different production scales.

Apply to:

1.Construction waste disposal site with fixed production site and less frequent movement;

2. Large production lines can be built.

3. Closed production to thoroughly solve dust emission pollution.

Stationary construction waste disposal production line process:

Advantages of stationary construction waste disposal production line:

1. It is convenient for comprehensive management, has production and living facilities system, has comprehensive treatment conditions for environmental protection, and can effectively control production costs.

2. With installation and commissioning is completed, continuous production can be achieved, and the adjustment time spent on moving sites can be saved.

3. There are enough spare parts and spare parts storehouse to meet the needs of continuous production.

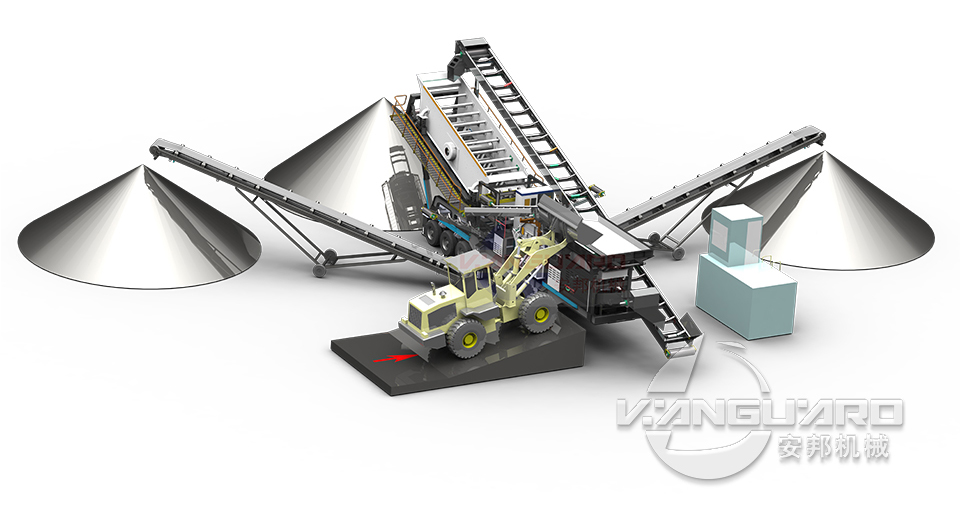

Mobile construction waste disposal equipment:

The mobile construction waste disposal production line consists of crushing machinery, screening machinery and auxiliary devices. The difference from various types of stationary

construction waste disposal production lines is that these mechanical devices are installed on one or more special chassis. Mobile construction waste disposal production line has been widely used in various fields such as ore crushing and construction waste disposal in China.

Mobile construction waste disposal production line process:

The construction waste generated after the building is demolished by blasting is pretreated to reach the particle size of the crusher, and then sent to the vibrating feeder by the excavator. The fine waste is pre-screened by the feeder and discharged. The large material enters the impact crusher and crushes. The iron remover is placed above the belt conveyor of impact crusher to separate the steel bars in the construction waste. After that, the material enters the mobile screening station. After screening, the large material returns to impact crusher for cyclic crushing , and the small material is transported to the finished material stack by the belt conveyor.

Performance of mobile construction waste disposal production line:

In addition to feeding system, crushing system, screening system and conveying system, mobile production line is equipped with self-supporting power device according to the mobility of mobile operation. The structure of the equipment is also different according to different crushing and screening processes.

1. Improve the utilization rate of equipment, have good mobility, and extend along with the site;

2. saving production costs: reduce the high cost of construction waste transportation;

3. easy to install: save the installation base costs and installation adjustment manpower;

4. convenient maintenance: can be directly shipped to the repair shop for repair;

5. Simplify the production process: advance along with the mining surface, simplifying the transportation process.

Pursuing the balance and unity of economic value, social value and environmental value is necessary for realizing the sustainable development of enterprises. Vanguard Machinery Technology Co., Ltd. has always adhered to the concept of innovation, green and environmental protection. With its rich experience and technology in mining machinery manufacturing, Vanguard Machinery has launched different solutions for the treatment of construction waste for customers. Vanguard Machinery shoulders the responsibility of promoting environmental protection, solving the urban troubles, and striving to be a gardener of urban construction.