Two Sets Of High-quality Mobile Production Lines From Vanguard Machinery Are Sent To Hubei

Date:2021-12-16Warm action and keep the machine warm in winter. Recently, the cranes and forklifts are roaring in the Henan Vanguard Machinery production workshop, two sets of tire-type mobile plants are ready for shipment in the preparation area. Workers are busy and orderly inspecting and loading the trucks. The batch of equipment will be sent to Hubei Province to help high-quality development in the sand and gravel market.

Vanguard Machinery’s 220-240 t/h mobile crushing production line is composed of 106 jaw crushing plant and CH840 single-cylinder cone crushing plant for bluestone processing projects. The whole production line has a reasonable configuration, large crushing force, and wide adaptability, which can meet the crushing of most of the stone. The capacity of this production line can reach 220-240 t/h, and it can produce three kinds of finished materials: 0-5mm, 5-15mm, and 15-31.5mm.

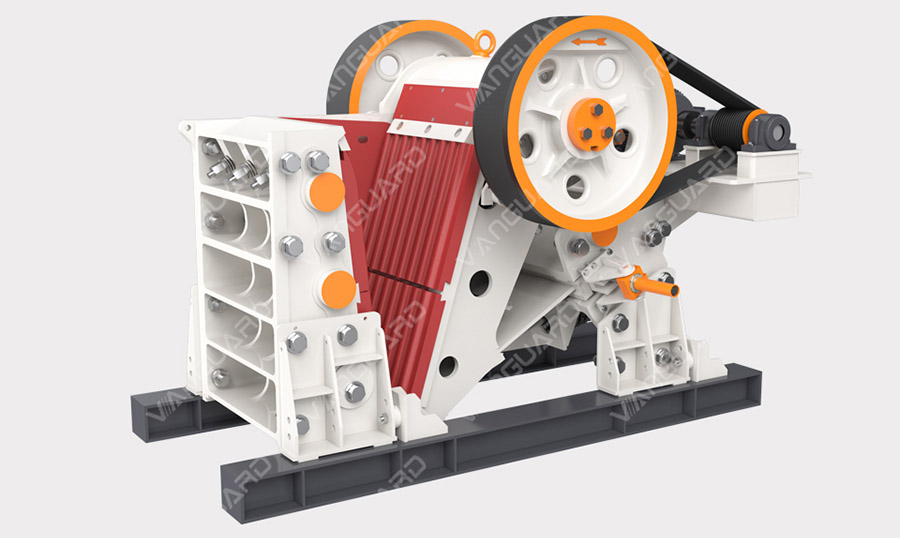

Vanguard Machinery's tire type 106 mobile jaw crusher plant is composed of a ZSW4211 feeder and 6CX106 jaw crusher. The integrated motor base design of the crushing host reduces the installation space of the equipment and makes the power output more stable.

The crusher adopts a "V-shaped" crushing cavity design. The crushing cavity structure and moving jaw movement trajectory parameters are optimized, and the large stroke maximizes the feed size, capacity and reduction ratio.

Compared with traditional jaw crushers, 6CX series jaw crushers pay more attention to details in terms of design and manufacturing. Using high-strength materials and advanced manufacturing processes have advantages of higher structural strength, equipment reliability, and a larger reduction ratio, higher capacity, lower overall processing cost.

Vanguard Machinery tire-type CH840 mobile single-cylinder cone crusher plant is composed of CH840 cone crusher and 3YA2160 vibrating screen. The key parts of this series of single-cylinder cone crushers adopt non-destructive inspection and acceptance with higher body strength, more reliable operation. Optimized crushing cavity design, ensuring the high efficiency of lamination crushing and the crushing effect of the equipment is not affected by the wear of the liner.

The positive pressure dust-proof system keeps the internal pressure of the crushing cavity higher than the external pressure, effectively reducing the dust or other small particles entering the crushing cavity to pollute the lubricating oil and damage the bearings, improve the service life of the crusher, and reduce the maintenance workload.

The integrated design of hydraulic station and lubrication station saves installation space; The hydraulic system is designed with a high-pressure method to meet ordinary pressure requirements. There is a higher pressure margin when the equipment is running, which improves the reliability of the hydraulic system.

Sincere cooperation and mutual benefit with a win-win situation. Vanguard Machinery has the most comprehensive product series of mobile crushing plants for coarse crushing, medium crushing, fine crushing, ultra-fine crushing, sand making, and screening. Compared with stationary production lines, the mobile crushing plant has a short engineering cycle and quick transition follow-up. It is more economical and eco-friendly does, which is not only reduces the investment risk and opportunity cost of investors but also avoids the demolition work after the project ends. It can be widely applied in open-pit mining, construction waste crushing, urban road construction, concrete aggregate recycling, etc. In the future, Vanguard Machinery will adhere to the fine series of products, improve the supporting products, and win the trust of the majority of users with excellent quality and good service.