The Pioneer of Complete Crushing Plant –Jaw Crusher

Date:2021-04-21Jaw crusher is an indispensable coarse crushing equipment in mine crushing and aggregate production lines. It can be said to be at the pioneer position in the entire crushing plant. As the primary crusher, it can process various ores with compressive strength not higher than 320MPa to medium particle size at one time. Jaw crusher is often combined with cone crushers, impact crushers, sand making machines to form a complete set of aggregate production line, which are widely used in mining, metallurgy, chemicals, building materials, electricity, water conservancy, transportation and other fields. The capacity can be from hundreds of tons to thousands of tons, and the finished products are cubic structure, free of tension and cracks, which have a good shape.

At present, Vanguard Machinery manufactures jaw crushers include PE/PEX jaw crusher and 6CX series European jaw crusher. There are stationary and mobile types that can be chosen based on the operating conditions and actual needs.

Advantages of PE/PEX series jaw crusher:

Deep cavity crushing: Optimized deep cavity crushing, no dead zone, greatly improved feeding and crushing efficiency, and good energy-saving effect.

Mature technology and long service life: Learn from the world's manufacturing technology, digitally analyze the operation of each component, and the internal structure is exquisite, which greatly extends the service life of the equipment.

Strong load-bearing capacity and high stability: Larger forging blanks process heavy-duty eccentric shafts, high-manganese steel jaw plates and high-grade cast steel movable jaw assemblies, and the equipment has stronger load-bearing capacity and higher stability.

Simple structure and convenient maintenance: Under the basic principle of compound pendulum, redundant parts are simplified, the overall structure of the equipment is simple, the crushing ability is strong, the operation and maintenance are convenient, and the operating cost is low.

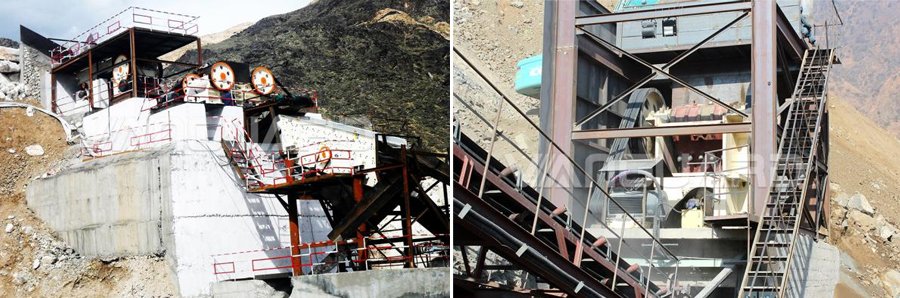

Customer site of PE/PEX series jaw crusher:

Advantages of 6CX series European jaw crusher:

1. The crusher processes V structure chamber, optimum configuration crushing chamber and trajectory parameters of moving jaw. The super-large crushing stroke maximizes the feeding size, capacity and reduction ratio.

2. Replacing the original rigid foot connection with elastic limit block and rubber damping device which effectively absorbs peak load of vibration, so as to reduce the impact force between crushers and foundation and prolong the equipment service life.

3. Replacing traditional plates with wedges, the discharge opening can be adjusted more simply.

4. Integrative motor cabinet reduces mounting space and makes the power output more stable. Oversized tapered roller bearing with uniform internal and external bearing models reduces the number of spare parts.

Customer site of 6CX series European jaw crusher:

The PE/PEX series jaw crusher has advantages in price. It is suitable for production lines with low investment and low capacity requirements. For large-scale, high-yield, environmentally friendly and energy-saving production lines, the 6CX series European jaw crusher is more efficient, more convenient in operation and maintenance, and more environmentally friendly. Our technical engineers will recommend a more suitable choice for you according to your requirements for equipment capacity, finished product size, budgetary funds, site size. Please feel free to contact us at any time.

Zhengzhou Vanguard Machinery Tech Co., Ltd always adheres to the business philosophy of “cooperation, sharing and win-win”, and strictly follow the policy of “quality first, customer first”. We care about the all-round needs of customers, and implement full-process quality control in accordance with ISO9001 standards to ensure that the equipment supplied brand new, advanced, mature, complete, safe and reliable. We are responsible for every process, every product and every user.