Principles, Advantages and Disadvantages of Mainstream Crushing Equipment

Date:2021-10-19Crushing equipment is an indispensable part of crushing, sand making, grinding, and other processes. However, there are many types of crushers on the market, so how do choose suitable and satisfactory products? First of all, you need to know the applicable conditions, advantages and disadvantages of these crushers.

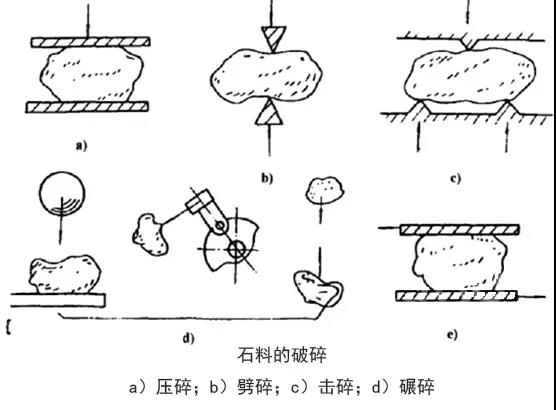

Crushing method

The crushing method of the crusher is divided into squeezing, splitting, crushing, shearing, impact or hammer, etc. Generally, there is no single action mode but a mix of multiple action modes.

Squeezing and crushing:The working face of the crushing machine applies pressure to the material sandwiched between it, and the material is crushed when the compressive stress on the material reaches the limit of its compressive strength.

Splitting, shearing and crushing:The edges of the crushing working face are wedged into the material to generate tensile stress inside. When the value exceeds the tensile strength limit of the material, the material splits and locally produces powder at the point of contact between the sharp edge and the material.

Bending, breaking and crushing:The materials sandwiched between the working surfaces, such as simply supported beams or multi-supported beams subjected to concentrated forces, are mainly subjected to bending stress, but are subject to splitting at the contact point of the working surface.

Squeezing and shearing:A combination of squeezing and shearing.

Impact crushing:Impact crushing includes the impact of the high-speed moving crusher on the material to be crushed, the impact of the high-speed moving material on the fixed wall and the mutual impact of the moving materials.

Analysis of the crushing mechanism, advantages and disadvantages of different crushers

Crushers can be divided into three categories according to the granularity of feed and product:

Coarse crusher:crush from 1500~500mm to 350~100mm;

Medium crushing crusher:crushing from 350~100mm to 100~40mm;

Fine crusher:crush from 100~40mm to 30~10mm.

Crushers can be divided into different working principles and structural features:

1. Jaw crusher

The jaw crushing work is intermittent, and the rock material is squeezed to complete the crushing by the swing of the fixed jaw and the movable jaw. Simple pendulum jaw crusher are rarely used in practice now, mainly compound pendulum jaw crusher.

Application:It is suitable for a wide range of materials, both soft and hard, especially the coarse and medium crushing of hard stones.

Advantages:Simple structure, reliable work, lighter weight, cheap price, small size, low configuration height, large feed opening size, easy adjustment of the discharge opening, simple maintenance, and economical operating costs.

Disadvantages:Easy wear of liner, high content of needle flakes in the product, and feeding equipment are generally required.

2. Cone crusher

The work of the cone crusher is continuous, and it crushes the stone by the eccentric movement of the moving cone. At the same time, due to the tangential movement of the moving cone and the fixed cone, the stone is also subjected to shearing and grinding. Therefore, its working mechanism It is a combination of extrusion, shearing, and milling methods.

Application:Mainly used for medium or fine crushing of various stone materials. At the same time, according to its different structure (suspended shaft type and supporting shaft type), it can also be used for coarse stone crushing (suspended shaft type is used less).

Advantages:large crushing ratio, high efficiency, low energy consumption, less dust, uniform product size, stable work, low failure rate, and not easy to be crushed.

Disadvantages:The more complicated structure and maintenance, high body and the expensive price.

3. Impact sand making machine

The work of the impact sand making machine is continuous. It uses high-speed moving materials to strike iron, strike each other, and friction between the materials to crush. There are two crushing methods: crushing between stones and crushing between stone and plate.

Application:Crushing between stones is suitable for abrasive materials with medium hardness and above. The finished product has a better grain shape and slightly more powder content. Crushing between stone and plate is suitable for materials with low abrasiveness below medium-hardness, with higher crushing efficiency, higher wear cost of the peripheral guard plate, and poorer grain shape of the finished product.

Advantages:low energy consumption, high capacity, large reduction ratio, the small size of the equipment, easy operation, convenient installation and maintenance. It has a shaping function, cubic product, large bulk density, and great less wear of the machine's impact plate during operation.

Disadvantages:The complicated maintenance and high cost. Generally, the maximum feed size does not exceed 60mm, which is suitable for fine crushing and sand making.

4. Hammer crusher

The hammer crusher also works continuously, using the hammerhead on the high-speed rotating rotor to crush the stone.

Application:Suitable for medium and fine crushing of medium and low hardness and non-abrasive stones (compressive strength less than 100MPa). When there are grate bars, it can also be used for sand making but it has been rarely used.

Advantages:large reduction ratio, high output, and more fine materials.

Disadvantages:The hammerhead wears quickly and needs to be replaced frequently. The large work dust and viscous materials with a raw material moisture content of more than 12% cannot pass effectively.

5. Impact crusher

Impact crusher is a machine that uses impact energy to crush materials. Adjusting the gap between the impact frame and the rotor can achieve the purpose of changing the size and shape of the material discharged.

Application:Mainly used for medium crushing and fine crushing of stones below medium hardness, and the shape of the crushed stones is better.

Advantages:Small size, simple structure, uniform product size, selective stone crushing, and high capacity.

Disadvantages:The flat hammer and the impact plate are particularly easy to wear, especially for crush hard rocks, which are more severely worn and need to be replaced frequently. It is not suitable to crush plastic and viscous materials.