What Is Aggregate? What Are The Common Aggregate Production Lines?

Date:2021-12-22The green development of the sand and gravel industry has always attracted the attention of industry professionals. Studies show that sand and gravel aggregates have become the second-largest consumable for human beings after only freshwater. High-speed railways, roads extending in all directions, and row upon row of tall buildings, what kind of engineering does not need to consume an amount of sand and gravel aggregates? So what is aggregate?

What is aggregate?

Aggregate plays a role in filling and supporting concrete in a loose granular form, which improves the durability and stability of concrete.

According to the source, it is divided into natural, artificial and regenerated.

According to the diameter, it is divided into coarse and fine aggregate.

According to the density, it is divided into ordinary and light aggregate.

Fine aggregates with a particle size of 0.15-4.75mm are commonly called sand, and coarse aggregates with a particle size of 4.75-9.0mm are commonly called stone. As natural sand and stone aggregates are gradually depleted, it is compared fiery of the market for artificial sand and stone, various slag, rocks, waste materials, etc. can be processed into the required particle size through mechanical equipment.

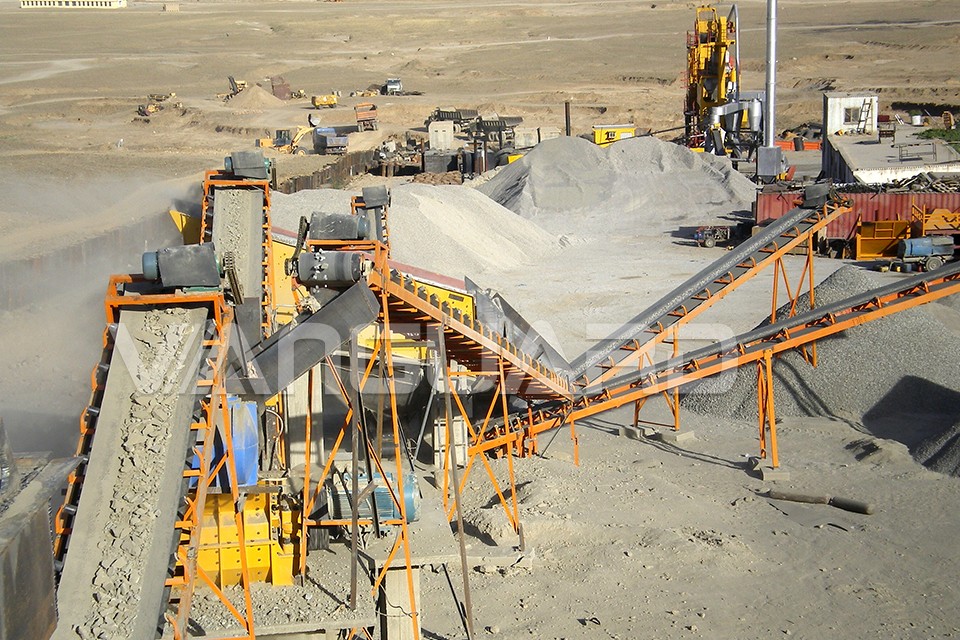

Aggregate production process

The choice of aggregate production line is an important part of modern aggregate mine production. The complete production line is composed of four major systems: feeding system, crushing and sand making system, screening system, and sorting system.

1. pretreatment

This stage is mainly for pre-crushing the bulk materials in the raw ore of sand and gravel aggregates by hammering, and sorting the unsuitable debris among them, and remove waste wood, plastics and other debris then easy for the next treatment process. And remove the scrap iron in the aggregate in the first magnetic separation. g>

2. Crushing and sand making

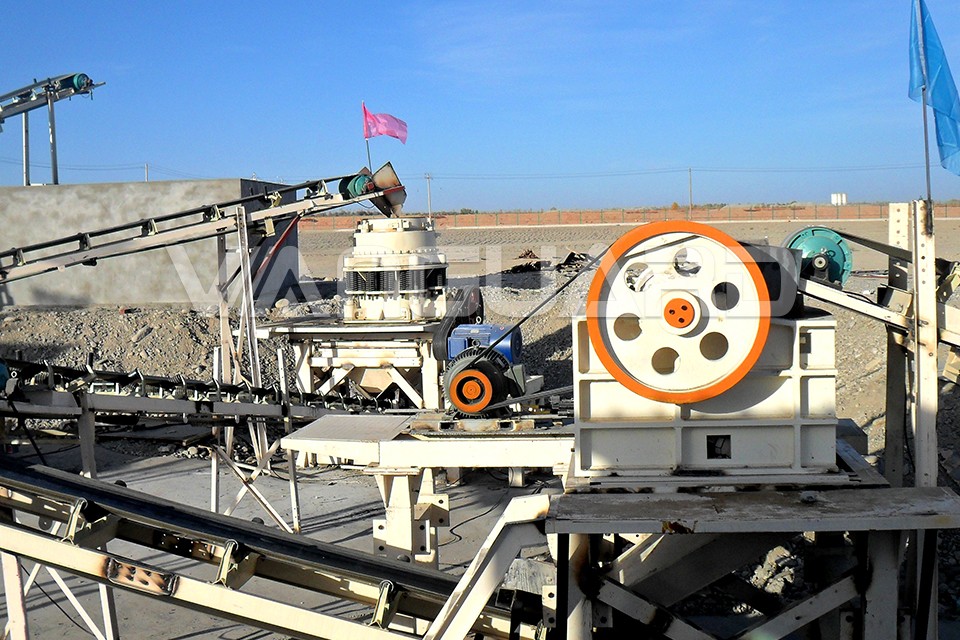

First, the raw material is for primary crushing by jaw crusher. Then uniformly fed by a vibrating feeder, the jaw crusher uses the movement of the jaw plate to crush large pieces of sand and gravel aggregates into smaller particle sizes. The coarsely crushed materials are transported to the transfer pile by conveying equipment. Then, the material can be finely crushed and shaped using the sand making machine, and the grain size of the aggregates after being processed is uniform by the sand making machine.

3.Primary screening

In this stage, screen the coarsely crushed concrete aggregate into blocks of 0-40mm and crushed materials of 5 mm or less by a circular vibrating screen. Among them, the 5-40mm coarse aggregate after collecting is directly used for general C15-C20 concrete production. The fine aggregate is transported to the transfer pile for the next process.

4. Secondary crushing and screening

For the secondary crushing, crush the fine aggregate again by a ball mill.. The secondary screening divides the crushed aggregate into 5-20mm high-quality recycled aggregates that can be used for C25-C30 concrete manufacturing. The tertiary screening selects high-quality recycled fine aggregates of 0.15mm-5mm and below 0.15mm fine powder.

Common aggregate production line configuration

Generally speaking, the configuration of the aggregate production line needs to combine the user's working conditions, capacity in an hour, finished product size, energy consumption, and other requirements. There are common equipment combination forms of the aggregate production line:

1. Jaw crusher + cone crusher + sand making machine + auxiliary equipment (feeder, conveyor, hoist, etc.)

2. Jaw crusher + impact crusher + sand making machine + auxiliary equipment;

3. Hammer crusher + high-efficiency fine crusher + impact sand making machine + auxiliary equipment.

Advantages of finished aggregate processed by aggregate production line:

1. It will save cement consumption for a very good particle gradation and a small accumulation of porosity.

2. It has very stable physical and chemical properties and better durability.

3. It contains less impurities and will not affect the setting and hardening of cement, which can effectively increase the service life of engineering buildings.

4. The mechanically processed aggregate has higher hardness and firmness and has a more obvious frame effect.