What Are the Common Cone Crushers?

Date:2022-08-19The cone crusher adopts new technology research and development, optimize the crushing cavity type, and has high crushing efficiency. It is suitable for crushing stones with medium and above hardness and high hardness. The cone crusher is equipped with different types and models for different stone materials and different production needs. In this article, we will briefly introduce the cone crusher for your reference.

Cone crusher is mainly divided into two types: hydraulic cone crusher and spring cone crusher, and hydraulic pressure is divided into two types: single-cylinder and multi-cylinder.

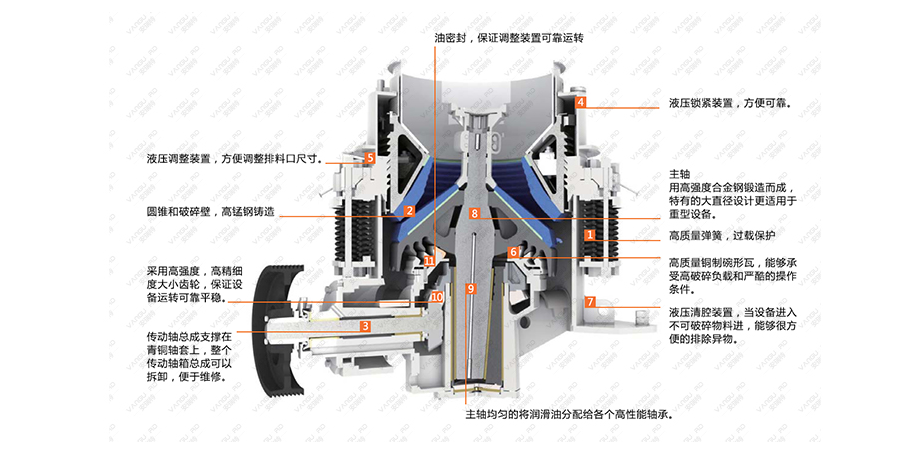

1. CS/CH series single-cylinder cone crusher

CS/CH series single-cylinder hydraulic cone crusher has a larger feeding port, which can exert greater performance and can be applied to various crushing processes. It is widely used in medium crushing to ultra-fine crushing, and stationary to the mobile crushing plants.

1. Feed size:0-370mm

2.Capacity:15-2200t/h

3. Power:90-750kw

4. Model:CS820/830/840/860; CH820/830/840/860/870/880

Working principle:

CS/CH series single-cylinder hydraulic cone crusher is to adjust the hydraulic cylinder at the bottom of the moving cone to make the moving cone move up and down so as to easily adjust the size of the discharge port and the size of the product. It is driven by the motor to drive the pinion of the crusher, the pinion drives the large gear, the large gear assembly (large gear, large gear frame, eccentric steel sleeve) drives the eccentric sleeve assembly (eccentric cylinder liner, eccentric copper sleeve) and the main shaft assembly (spindle), inner cone, inner cone liner), take the theoretical vertical line as the center, revolve in the copper bushing, and the main shaft assembly can realize autorotation with the center line of the main shaft in the eccentric copper bushing. When the machine is running empty, the eccentric sleeve assembly holds the main shaft assembly and revolves with the large gear. When the material is added to the crushing chamber, the main shaft assembly (main shaft, inner cone) slowly moves in the eccentric copper sleeve under the resistance of the material of rotation. The running track of the inner cone seems to swing back and forth in the crushing cavity, and rotate slowly at the same time. The material is squeezed and broken by the oscillating inner cone, and the connection between the support sleeve and the frame is pressed by the hydraulic cylinder. When the metal falls into the crusher When there are unbreakable objects such as blocks, the moving cone of the single cylinder is held up by the bottom hydraulic piston, which plays the role of adjustment of the discharge port, iron pass-through protection and repeated ups and downs to remove the blockage. (See: CS/CH Series Single Cylinder Hydraulic Cone Crusher Model Parameters)

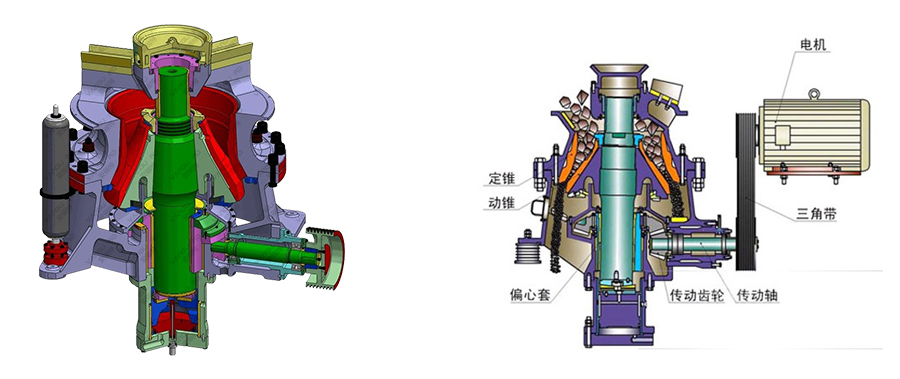

2. CP series multi-cylinder hydraulic cone crusher

CP series multi-cylinder hydraulic cone crusher adopts hydraulic protection, hydraulic cavity cleaning with a high degree of automation. In the case of iron pass-through and momentary congestion, the machine can lift the top hydraulically and discharge automatically, which eliminates the trouble that the original spring cone crusher needs to be shut down for manual discharge, greatly reducing the maintenance rate and improving the production efficiency. The crushing efficiency is high, the wearing parts are low, the finished product is cubic after crushing, and the fine-grain content is high, which can meet the needs of some high-quality aggregates.

1. Feed size:0-350mm

2.Capacity:55-550t/h

3. Power:75-315kw

4. Model:CP200/300/400/500/800

Working principle:

CP series multi-cylinder hydraulic cone crusher uses the principle of lamination crushing to crush materials. When working, the motor drives the pulley or the coupling, and the transmission shaft and the cone part make the eccentric shaft perform periodic swing motion under the axis line. After the material enters the crushing cavity from the feed port, it is crushed due to the mutual impact of the eccentric shaft and the concave squeezing, grinding, and kneading. After many times of squeezing, impact and bending, the material crushed to the required particle size falls under the action of its own gravity and is discharged from the bottom. (See: CP series multi-cylinder hydraulic cone crusher model parameters)

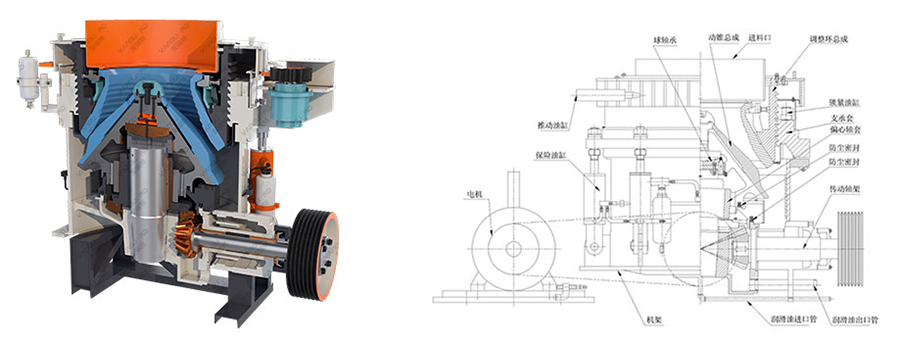

3. CSV series hydraulic cone crusher

CSV series hydraulic cone crusher is suitable for crushing various ores and rocks with medium or above hardness. It has the characteristics of reliable structure, high production efficiency and convenient adjustment. It is ideal equipment suitable for crushing various hard and medium hardness ores and rocks in large factories, widely used in metallurgy, construction, hydropower, transportation, chemical industry, building materials and other industries.

1. Feed size:0-178mm

2.Capacity:18-725t/h

3. Power:45-315kw

4. Model:CSV60/110/132/160/200/250/315

Working principle:

When the CSV series hydraulic cone crusher is working, the motor drives the pulley or the coupling, and the transmission shaft and the cone part make the eccentric shaft do periodic swing motion under the axis line. After the material enters the crushing cavity from the feed port, it is crushed due to the mutual impact of the eccentric shaft and the concave squeezing, grinding, and kneading. After many times of squeezing, impact and bending, the material crushed to the required particle size falls under the action of its own gravity and is discharged from the bottom. (See: CSV series hydraulic cone crusher model parameters)

CSV series hydraulic cone crusher adopts special crushing frequency and eccentric distance so that the content of fine particles in the crushed products is higher, and the content of particles smaller than the closed side discharge port can reach 80%, which improves the processing capacity of subsequent processes and reduces comprehensive energy consumption. Moreover, the safety cylinder can automatically control the overload protection and cavity cleaning functions, eliminating the trouble of the original spring cone crusher needing to stop for manual discharge, greatly reducing the maintenance rate and improving the production efficiency. The hydraulic lubrication combined oil station is small in size with simple wiring.

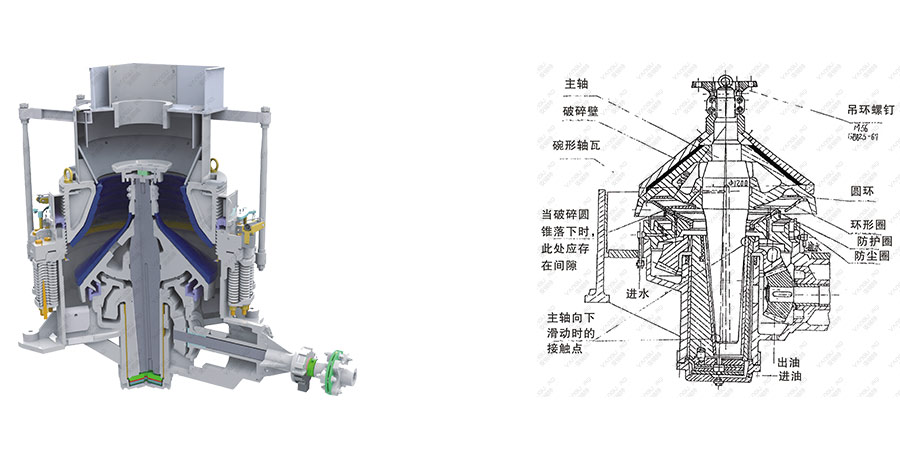

4. PY series spring cone crusher

The spring safety system of the PY series spring cone crusher is an overload protection device, which can make metal foreign matter pass through the crushing cavity without harming the machine. It adopts two sealing forms of dry oil or water to isolate the stone powder from the lubricating oil and make it work normally. The type of the crushing cavity of the spring cone crusher is determined by the use of the ore, and the standard type is suitable for medium crushing; Medium size is suitable for fine crushing; The short head type is suitable for superfine crushing.

1. Feed size:0-178mm

2.Capacity:20-300t/h

3. Power:30-260kw

4. Model:PYB600/900/1200/1750/2200; PYD600/900/1200/1750/2200 PYZ900/1200/1750/2200

Working principle:

The working part of the cone crusher is two truncated cones, one is a fixed cone and the other is a moving cone. The fixed cone is stationary and is a part of the frame. The lower end of the moving cone is movably inserted into the eccentric bushing. Therefore, the central axis of the fixed cone intersects with the central axis of the moving cone to form an oblique angle. When the central axis of the moving cone rotates around the central axis of the fixed cone, the moving cone is eccentrically moved along the inner surface of the fixed cone. In the section where the moving cone is close to the fixed cone, the material there is squeezed, impacted and bent by the moving cone to become a crushing cavity; Where the moving cone deviates from the fixed cone, the crushed material is discharged from the bottom of the cone under the action of its own weight, which becomes the discharge port, and the material is loaded from the feed port. (See: PY series spring cone crusher model parameters)

The model parameters of cone crushers produced by different manufacturers are different, and the required feed particle size, output, and finished product particle size are also different. You can contact the manufacturer to recommend the appropriate equipment model for you according to your actual needs.