Analysis and Treatment Methods of Common Failures of Single-cylinder Cone Crusher!

Date:2022-08-25Single-cylinder cone crushers are widely used in medium to ultra-fine crushing, and stationary to mobile crushing plant. Its reasonable design, perfect combination of eccentricity (stroke) and cavity shape, high capacity and excellent grain shape, bring high benefits to customers. However, cone crushers will always fail for some reasons, affecting production. This article will briefly introduce the common failure causes and treatment methods of cone crushers, hoping to help everyone.

1. The crusher cannot be started

Fault reason 1: The oil pump cannot run

Treatment method: Check the electrical circuit and the oil pump motor starter.

Fault reason 2: The low power of the oil pump, and there is no signal of the crusher is allowed to start.

Treatment method:

1)Check the lubricating oil, do not overflow the sealing cylinder to cause loss;

2)Then check the oil pipe, there must be no leakage;

3)Clean the oil filter element, and replace the oil filter element if necessary;

4)Check the power of the oil pump, replace the oil pump if necessary, and then run the oil pump to check the operation of the oil return switch.

Failure reason 3:The oil pump rotates, but there is no signal of the crusher is allowed to start.

Treatment method:

1) Cut off the main motor of the crusher, and check the work of the thermal switch;

2) Check whether the pinion shaft lubricating oil pump is interlocked with the main motor, check the pinion shaft lubricating oil pump motor protector and other electrical circuits.

Failure reason 4:The oil pump is running, and there is a signal of the crusher is allowed to start.

Treatment method:Check the starting device and other electrical circuits of the main motor.

Failure reason 5:The oil cannot be returned to the tank (in cold weather)

Treatment method:

1) Start the oil pump and let it run for about 30 seconds;

2) The connecting line crosses the oil return switch, so that the signal the crusher is allowed to start will appear, start the crusher and let it run for about 20 seconds; After 40 seconds, disconnect the oil return switch connection line, if there is enough oil to return to the oil tank, the crusher will continue to work, if not, the oil return switch will cut off the main motor of the crusher;

3) Repeat the above steps after a few minutes.

2. The crusher makes an abnormal sound

Fault reason 1:The helical gear is not installed correctly

Treatment method:

1) Incorrect gear meshing and insufficient backlash will cause the gear to make noise. Remove the pinion shaft assembly and measure the correct gasket thickness;

2) Adjust the side suction gap.

Fault reason 2:Serious wear of the middle friction ring

Treatment method:

The wear of the middle friction ring under the eccentric sleeve leads to the reduction of the backlash, and if the backlash is too small, there will be noise in the gear. Turn off the crusher, replace the friction ring, and adjust the backlash again.

Failure reason 3:The stone in the crushing cavity is blocked or the crushing wall and the concave have metal collision

Treatment method:

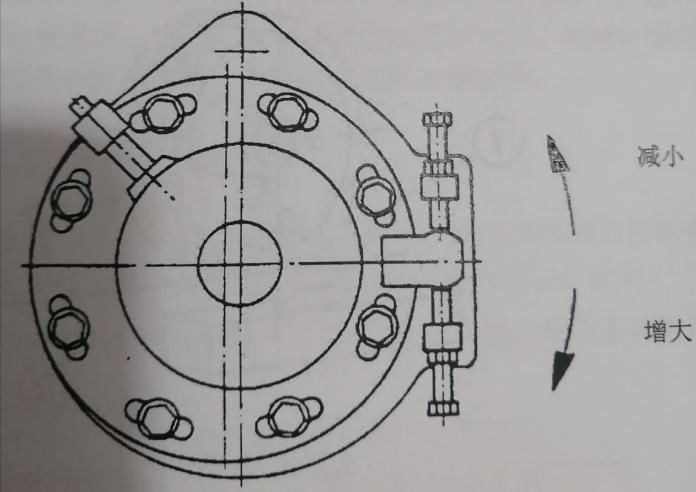

1) Check the workpiece condition and the ore discharge gap CSS, and check the ovality of the concave;

2) Increase the discharge gap CSS.

Failure reason 4:The sliding bearing makes noise

Treatment method:

1) Reduce the working load of the crusher and prolong the commissioning time;

2) Check the oil return filter and check the ovality of the concave.

3. The low working ability of the crusher

Fault reason 1:Slopes formed on the liner

Treatment method:

1) Check the feeding arrangement and make sure that the crusher is evenly filled with material;

2) Check the feeding gradation, whether there is an excessive amount of stone smaller than the CSS of the discharge port or the feeding ratio of the larger size is too high.

Fault reason 2:V-belt slips

Treatment method:

1) Check the tension of the belt and tighten it if necessary;

2) Replace the belt and check the belt groove of the pulley.

Failure reason 3:The feed changes

Treatment method:change the feed gradation, the hardness and gradation of the material will affect the working ability of the machine.

Failure reason 4:There is stone overhead at the feeding port

Treatment method:Check the feed height, if possible, limit the larger size of the feed, or change the crushing cavity.

4. The oil temperature is too high

Fault reason 1:Thermal protection triggered

Treatment method:

1) Check whether the cooling fan is working;

2) Check the fan motor and starter;

3) Check the radiator control thermal switch;

4) Check the heat sink and clean the inside and outside.

Fault reason 2:The oil cooler runs continuously

Treatment method:

1) Check the cooling control thermal switch;

2) Check the heat sink and clean its inside and outside;

3) Check whether the pressure reducing valve (bypass) is closed.

Fault reason 3:low oil flow

Treatment method:

1) Clean the filter and replace the filter element if necessary;

2) Check the power of the oil pump, and replace the oil pump if necessary;

3) Check the oil pipe for leakage.

Fault reason 4:Bearing damage

Treatment method:If the above methods cannot reduce the oil temperature, close the crusher, carry out mechanical inspection, and check the oil return filter.

5. The oil filter is often blocked

Cause of failure:Contaminated oil

Treatment method:

1) Clean or replace the filter element;

2) In the first year of operation of the machine, regularly check the state of the oil, and replace the oil regularly according to the state of the oil monitored;

3) The dust seal is worn or damaged. Check the gap between the sealing cylinder and the dust-proof seal. If the gap exceeds a certain value, replace the dust-proof seal.

4) The overpressure dustproof sealing system cannot work. Overhaul the positive pressure dust seal system and check its operation.

The above are the reasons and solutions for some failures of the single-cylinder cone crusher. If you encounter other problems, you can consult the engineer for details.