What Are the Models of PCZ Heavy Hammer Crusher? How to Adjust the Size of the Outlet?

Date:2022-09-02PCZ heavy-duty hammer crusher, also known as heavy hammer crusher, can realize one-shot molding, the finished material has excellent grain shape and reasonable gradation, and is suitable for limestone, marble, granite, bluestone, feldspar, river stone, iron ore, dolomite, quartz stone, slag and other materials, widely used in mining, cement, construction sites, chemical industry, road construction, sand and gravel factories and other industries.

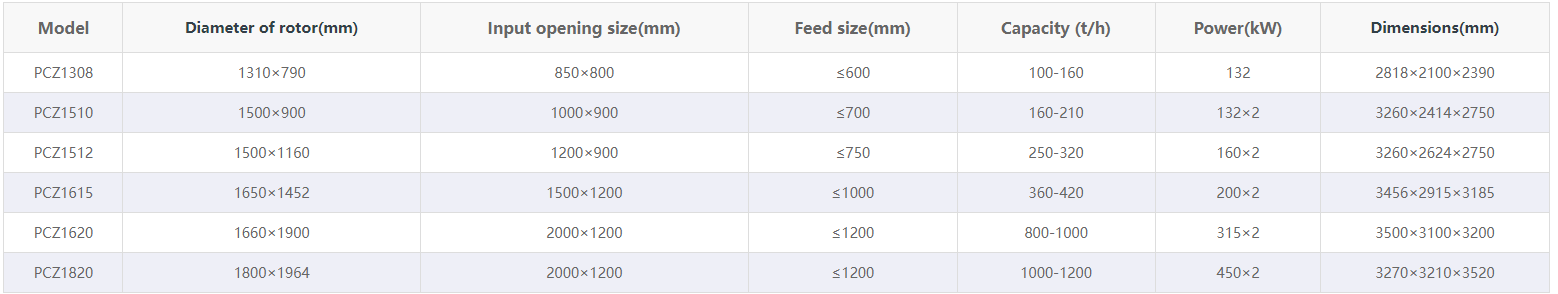

PCZ heavy-duty hammer crusher has a complete range of models, different models, rotor diameter, feeding port size, feeding granularity, processing capacity, motor power, external size, etc., customers can choose the appropriate equipment according to their actual needs. The commonly used PCZ heavy hammer crusher models are PCZ1308, PCZ1510, PCZ1512, PCZ1615, PCZ1620, PCZ1820, etc. The following is an introduction to these models.

Real photos of PCZ heavy hammer crusher:

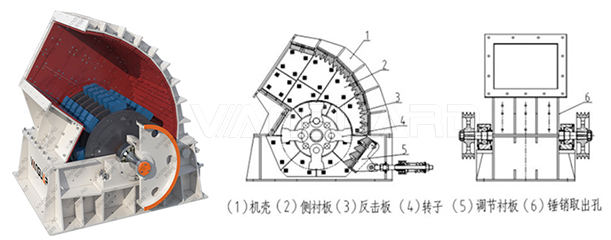

PCZ Heavy Hammer Crusher Composition:

A heavy hammer crusher is mainly composed of chassis, rotor, support plate, hammerhead and other parts, of which the rotor is the main working part, which consists of the main shaft, hammer disc, hammer head, hammer shaft, spacer, locking device, bearing, bearing seat , sealing device, etc., and the hammer head is the main working part, which is mainly broken by the impact of the high-speed rotary hammer.

The particle size of the finished product of the hammer crusher is directly related to the production progress and material output. Therefore, it is particularly important to effectively control the particle size of the finished product. If the particle size of the finished product is too large or too small, the gap between the hammer sieve plate, the diameter of the sieve hole, the ventilation volume, etc. There are many factors, which are briefly described below. (Note: The particle size of the finished product has been regulated during installation and debugging. If this happens in the future, you can contact professional and technical personnel to solve it.)

How to adjust the size of the discharge port of the PCZ heavy hammer crusher

1. The size of the discharge particle size of the hammer crusher is determined by the distance between the hammer head and the impact plate, and the gap and position of the impact plate of the hammer crusher can be adjusted;

2. The hammer crusher adjusts the discharge granularity to adjust the spring on the impact plate, and pressing the spring can make the impact plate move forward, thereby reducing the discharge port;

3. When the gap of the sieve plate is damaged by hammering, and the sieve plate aperture is too large to cause the particles to be too coarse, the cavity can be repaired or the sieve plate can be replaced;

4. When the sieve plate and the sieve frame are not tightly fitted or the side clearance is too large, the clearance can be adjusted.

In addition, after the material discharged from the PCZ heavy hammer crusher is screened by the screening equipment, some materials larger than the selection standard need to be transported to the crusher for secondary crushing until the size of the finished product discharge meets the selection requirements.

There are many ways to adjust the size of the discharge opening of the hammer crusher. Users can operate it according to the actual situation, so as to ensure the efficient operation of the equipment, and usually pay attention to daily maintenance and maintenance so that it can be used normally.