What is the Difference Between Jaw Crusher and Cone Crusher? Which Equipment is Better for Crushing Stone?

Date:2022-09-09Jaw crusher and cone crusher are commonly used crushing equipment, so what is the difference between these two crushing equipment? Which device is better to choose? This article will briefly introduce.

Simply speaking the difference between a cone crusher and a jaw crusher, the jaw crusher is mainly used for primary crushing and the quite large crushed stone. Stones with a size of about 1500mm are used for the primary crushing of stones. Larger stones are broken into stones with a diameter of less than 100mm to facilitate the production of the next crushing process. This kind of equipment has strong wear resistance, can crush large stones well, and reduce the wear and tear of the equipment.

Cone crusher is used for crushing medium-sized flakes, and is mostly used for secondary crushing. The cone crusher is specially designed for crushing hard stones, when the cone crusher crushes the hard stones, the safety device opens the protective equipment to prevent the equipment from being damaged. Therefore, when crushing this type of stone, choose a cone crusher.

Jaw Crusher:

Compared with the traditional jaw crusher, the jaw crusher is a new type of crusher developed after years of technical development. Compared with the traditional jaw crusher, it has stronger structural strength, higher equipment reliability, larger equipment deduction ratio and more uniform finished product particle size. It can crush limestone, granite, marble, basalt, iron ore, cobblestone, construction waste and other materials.

Cone Crusher:

Cone crusher is a new generation of multi-cylinder hydraulic cone crusher successfully developed by our company combined with rich field experience and exploration of new technologies and materials. It uses the principle of lamination to crush materials, and its high crushing efficiency, low wear of wearing parts, the cubic finished product, with high content of fine particles, which can meet the needs of some high-quality aggregates.

The difference between jaw crusher and cone crusher:

1. Overall structure

Jaw Crusher:

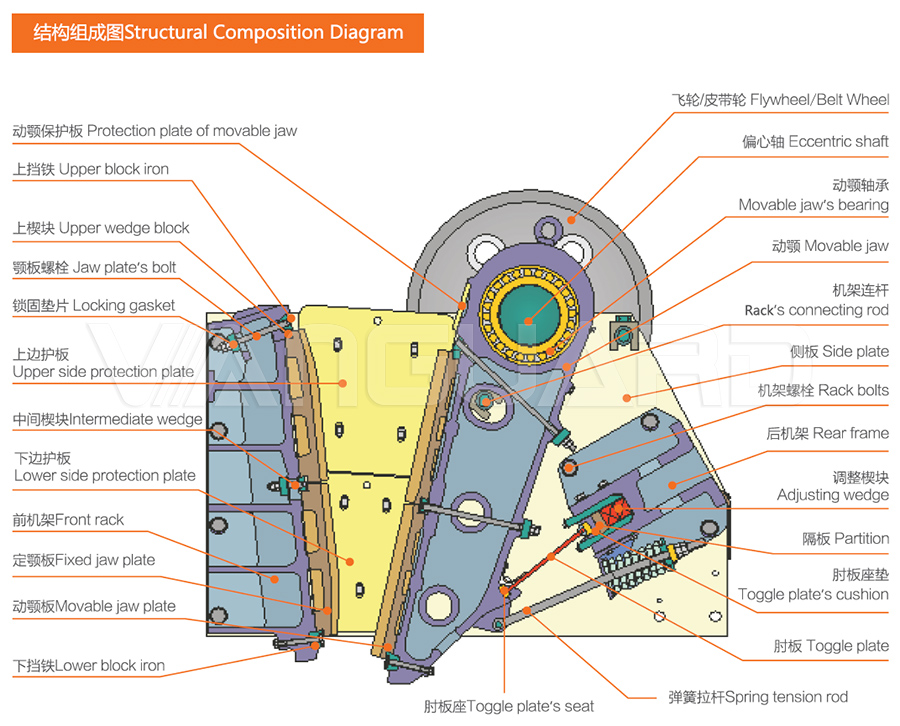

It is mainly composed of a frame, an eccentric shaft, a rotating part, a crushing cavity, a safety device, and a discharge port adjustment device. (Take 6CX series European jaw crusher as an example)

Cone Crusher:

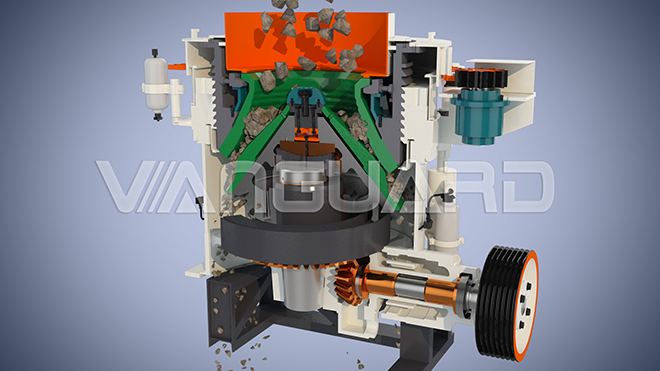

It is mainly composed of a moving cone, adjusting sleeve, feeding hopper, feeding tray, spherical bearing, main frame, eccentric sleeve, hydraulic automatic protection, main shaft, transmission shaft, pulley and so on. (Take the CP series multi-cylinder hydraulic cone crusher as an example)

2. Feeding requirements

Jaw crusher:The material should be evenly fed, and too much material should not be put in, otherwise the material will not be broken in time, and the crushed material will not be removed in time, resulting in material jamming in the crushing cavity.

Cone Crusher:Single-cylinder hydraulic cone crusher, multi-cylinder hydraulic cone crusher and Symons spring cone crusher without dividing plate all require evenly filling and feeding, mainly for the material to form lamination crushing in the crushing cavity to effectively improve crushing efficiency, reduce liner wear and energy consumption.

Advantages of jaw crusher and cone crusher:

1. Jaw Crusher:

1. High production efficiency

The structure of jaw crusher adopts the design of deep V crushing cavity, the cavity is deep but there is no dead zone, and the material will not be blocked in the crushing cavity, which can effectively improve production efficiency.

2. Long service life

The elastic limit block and rubber damping device are used to replace the original rigid foot connection, which can effectively absorb the peak vibration load, thereby reducing the mutual impact between the crusher and the foundation and improving the service life of the equipment.

3. Easy to operate

Wedge block adjustment is used to replace the traditional pad-type discharge port adjustment, which makes the discharge port adjustment to realize the stepless adjustment operation easier.

4. Design optimization

The integrated motor base design reduces the equipment installation space and makes the power output more stable. The super-sized tapered roller bearing has the same type of inner and outer bearings, which reduces the number of spare parts.

2. Cone Crusher

1. Various crushing cavity types

A variety of crushing cavity types, with strong applicability, can realize the transformation from ultra-coarse cavity type to ultra-fine cavity type and can adapt to a wide range of product particle size requirements.

2. High degree of automation

The hydraulic adjustment of the discharge port and the hydraulic cavity cleaning cylinder can quickly remove the accumulated materials and unbreakable objects in the crushing cavity, which can greatly shorten the downtime, with a high degree of automation and convenient maintenance.

3. Thin oil lubrication

Using a thin oil lubrication system, the parts lubricated by the cone crusher are mainly spherical bearings, main shaft bearings, eccentric sleeve bearings, bevel gears and drive shafts, etc. This design can avoid poor lubrication and effectively improve service life.

4. High crushing efficiency

Adopting the lamination crushing principle with a large capacity and high crushing efficiency. The finished product has a good particle shape, and the crushed product has uniform particles and is mostly in a cubic structure.

5. Less consumption of wearing parts

The cone crusher has a reasonable structure, reliable operation, and wear-resistant protection of its components, which can effectively reduce maintenance costs and low operating costs.

Jaw crusher and cone crusher have their own advantages. Both jaw crusher and cone crusher have better grain shapes, and the two complement each other. The specific choice of equipment mainly depends on the type and hardness of the material, finished product size, site and actual needs, users can make reasonable purchases under the guidance of professionals.