The Description of the Common Problems and Solutions of Impact Crusher

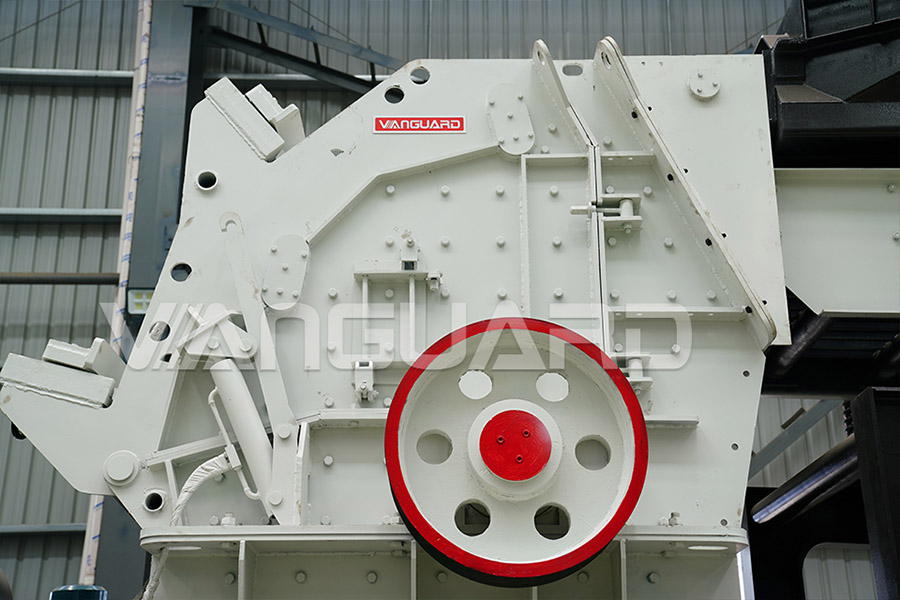

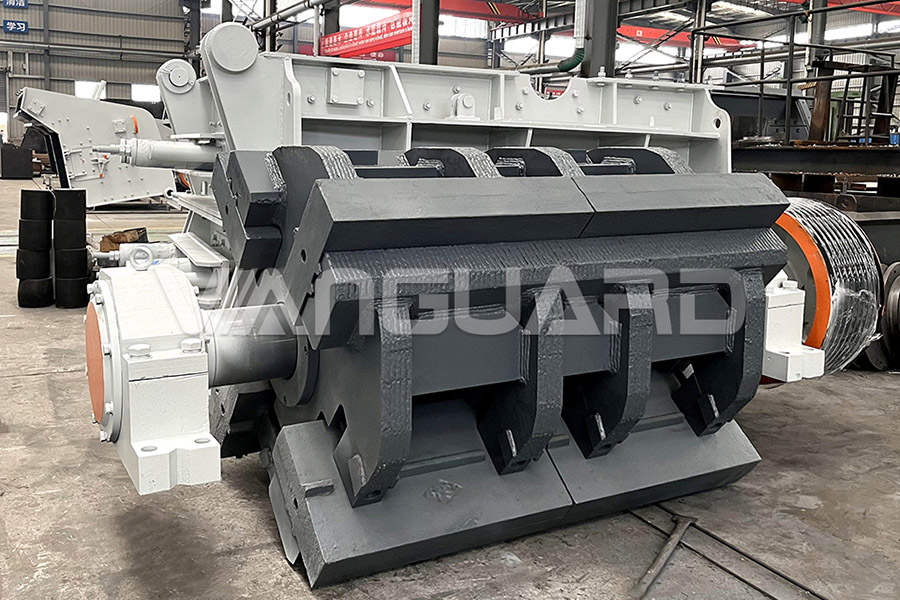

Date:2022-09-22The Impact Crusher is also called the Impact Breaker, which is a crushing machine that uses impact energy to break material. It has the advantages of large reduction ratio and cube shape, thus it is widely used in building materials, ore crushing, railway, highway, energy, transportation, cement, mining, chemical industry and other industries. While in the process of operation, it is inevitable that some problems will arise to affect production and reduce work efficiency due to improper operation or other reasons. This article will make a brief introduction on common problems and solutions of the Impact Crusher, for your reference.

Common problems and solutions of the Impact Crusher:

1. The machine does not work after startup

Check whether the material in front of the feeder falls into the crushing chamber due to the vibration of stopping the machine, which would causes the material to get stuck in the rotor. If so, it is necessary to clean the material in the crushing chamber and restart the machine will solve the problem.

2. Equipment bearing heats up

It should be checked whether the lubrication of the bearing is good. Lack of oil or too much oil will lead to bearing heating. Under normal circumstances, 50% volume of the bearing house should be filled with the lubricating oil. Another situation is that the lubricating oil is deteriorated and sticky, then it is necessary to clean the bearing and replace the lubricating oil.

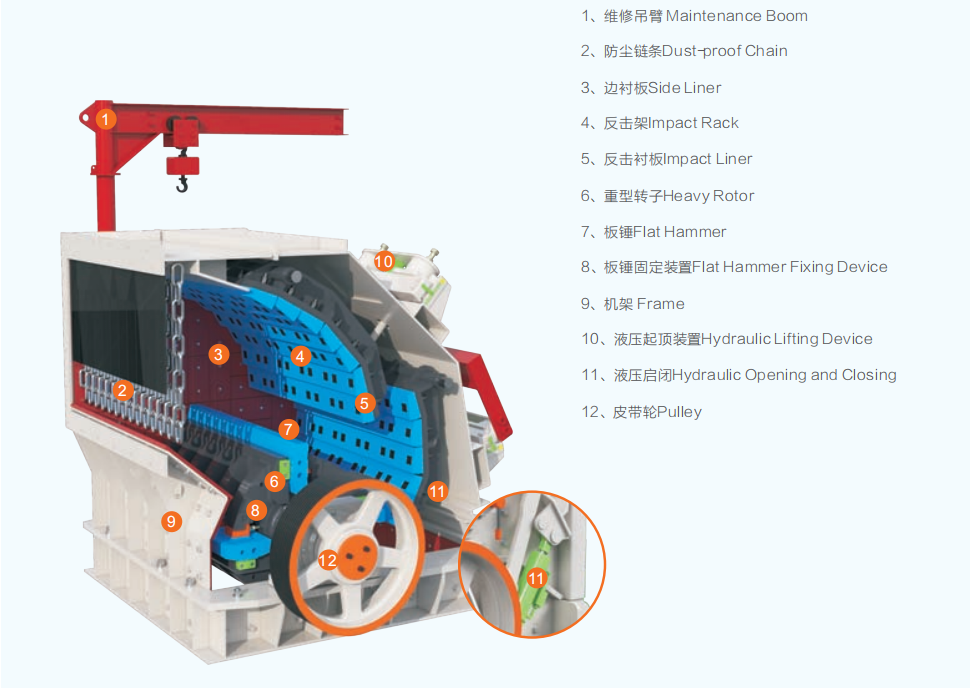

3. Abnormal vibration of equipment

Perhaps it is because the material feed size is too large, or the wearing parts are uneven worn, or impcat hammer needs to be replaced, or the rotor is imbalance and needs to adjust to reach balance. Check whether the anchor bolts of the device are tightened and properly strengthen it if needed.

4. The bearing bent or broken

The main reasons are long-term overload running of the host, improper heat treatment of the bearing, the hardness of the broken material exceeds the standard and so on. When handling this kind of problems, it is necessary to replace the new bearing, and pay attention to timely maintenance and overhaul in the future operation.

5. Sudden shut-down

There are many reasons that would lead to the sudden shutdown of Impact Crusher while it is in operation, such as the blockage of discharge outlet, belt slip, low voltage, bearing damage and so on. These problems should be eliminated one by one, such as clearing the blockage of the discharge outlet, tightening the belt, increasing the voltage and ensuring the stability of the voltage, replacing bearings, etc.

6. The spring part of the device is broken

The main reason of this problem is that the spring is not loosened when adjusting the discharge outlet. Therefore, the broken spring must be replaced in the process of treatment.

7. Abnormal sound inside the crushing chamber

The machine should be immediately shut down and check whether the crushing chamber contains any metal impurities or parts fracture, then clean the crushing chamber. Check the condition of fastening of the internal liner and the gap between the flat hammer and the liner, for that the gap is too small will also cause abnormal sound.

8. Flywheel rotation and crusher does not work

It is mainly because the damage of pull rod and its spring and pull rod nut tripping, which leads to the toggle plate slide out from the supporting slider, or the toggle plate broken off. Locate the cause and replace the damaged components.

9. The equipment smells of glue in operation

The main reason for this problem is that the belt slips, and it produces friction and heat with belt pulley to emit a pungent rubber smell, or the rotor is stuck. It is necessary to check the rotor in the machine chamber and solve it in time.

10. The discharging particle size is too large

It indicates that the flat hammer or the impact plate of the Impact Crusher is seriously worn, and the gap between the flat hammer and the impact plate is too large. It is necessary to adjust the gap between the front and rear impact frame, or replace the liner and the flat hammer. Adjust the position of the counter frame, so that the gap between the two sides and the frame liner is even. If the liner on the frame is seriously worn, replace it in time.

The above is the common problems and solutions of Impact Crusher. If you encounter other problems, you can consult us for more details. We can provide not only the equipment selection, but also the design and planning of the whole production line, equipment installation and debugging and technical training of field operators and so forth, so as to help you start production as soon as possible to generate revenue.