How many kinds of crushing methods are there in common stone crushers? Which crusher is good for crushing stone?

Date:2023-01-30

Stone crusher is the machine that use extrusion, splitting, bending, impact, crushing and other ways to crush large pieces of rock into broken pieces. Common stone crushers are mainly jaw crusher, impact crusher, hammer crusher, single-cylinder hydraulic cone crusher, multi-cylinder cone crusher, vertical shaft impact crusher. There are many types and models of this equipment. Which crusher should be selected? For this question, Vanguard Machinery will briefly do the following introduction for your reference.

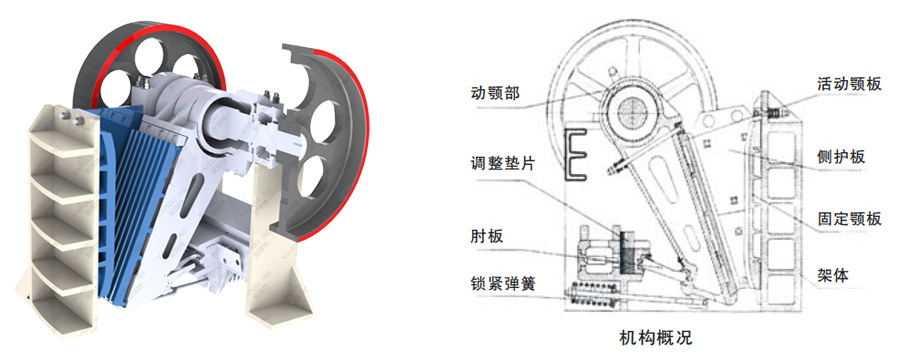

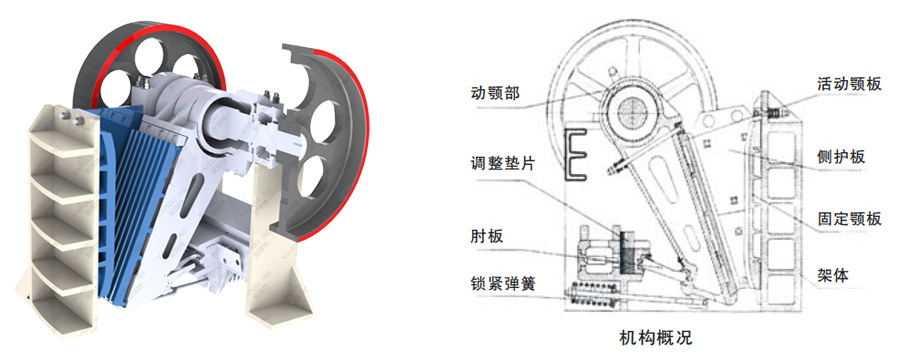

The jaw crusher is driven by the fixed jaw and the swinging jaw to crush the stone. The motor drives the belt and the pulley, and moves the swinging jaw up and down through the eccentric shaft. When the jaw rises, the angle between the elbow plate and the jaw becomes larger, thus pushing the jaw plate closer to the fixed jaw plate, and the material is crushed or split to achieve the purpose of crushing. When the jaw goes down, the angle between the elbow plate and the jaw becomes smaller, and the jaw plate leaves the fixed jaw plate under the action of the tie rod and spring, and the crushed material is discharged from the lower mouth of the crushing chamber.

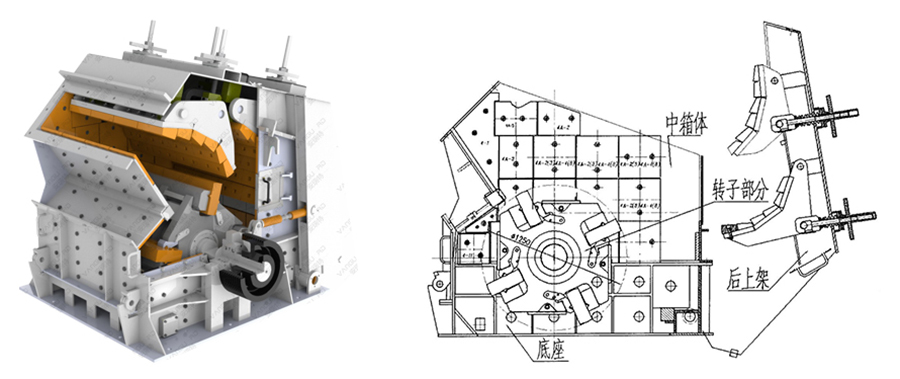

2、Impact crusher crushing method: impact + impact crushing type

2、Impact crusher crushing method: impact + impact crushing type

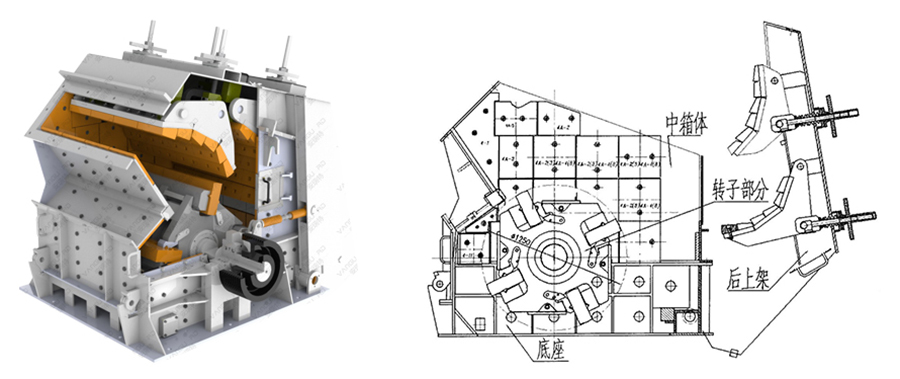

The rotor rotates at a high speed driven by the electric motor. When the material enters the flat hammer area, it crushes by the crushing the flat hammer on the rotor, then it is thrown to the counterattack device and crushed again, then it bounces back to the flat hammer area from the counterattack liner and crushes again. This process will be repeated, and the material enters the first, second and third counterattack chambers from large to small and crushes repeatedly until the material is crushed to the required size and discharged from the discharge port.

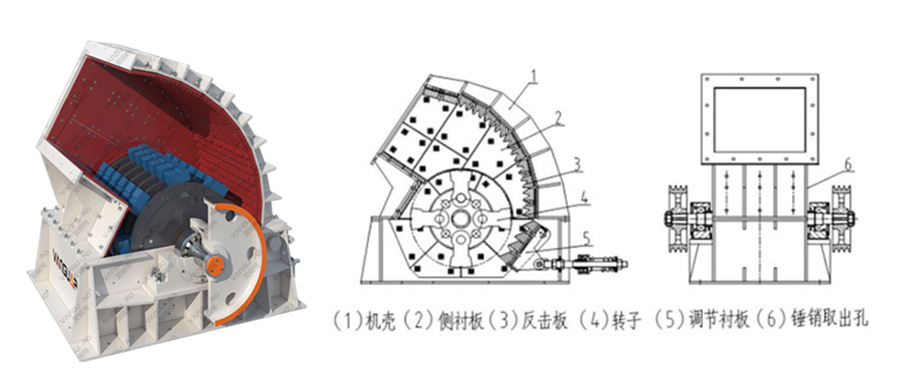

3、Hammer crusher crushing method: impact + impact crushing type

3、Hammer crusher crushing method: impact + impact crushing type

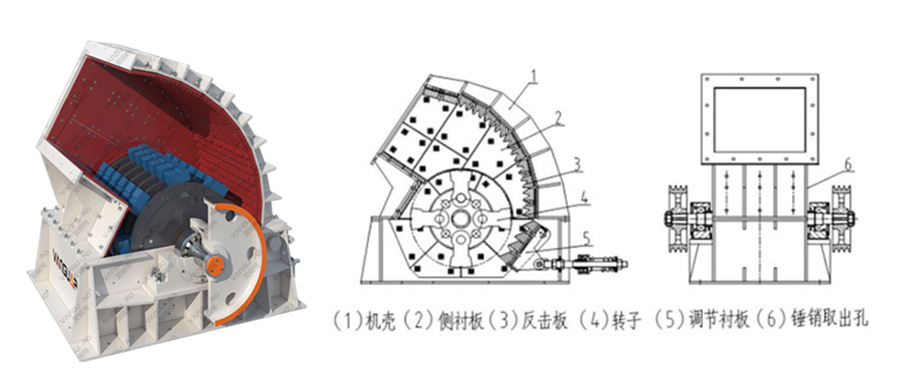

The material enters the crusher, crushes after the impact of the high speed rotating hammer head. The crushed material gets the kinetic energy from the hammer head, rushes to the baffle plate and screen bar in the frame, meanwhile the material hits each other and will be crushed several times. The material smaller than the gap of the screen bar is discharged from the gap, while the larger material is crushed again by the impact of the hammer head, grinding and squeezing on the screen bar. Then the material is extruded from the gap by the hammer head, so as to obtain the required size of the product.

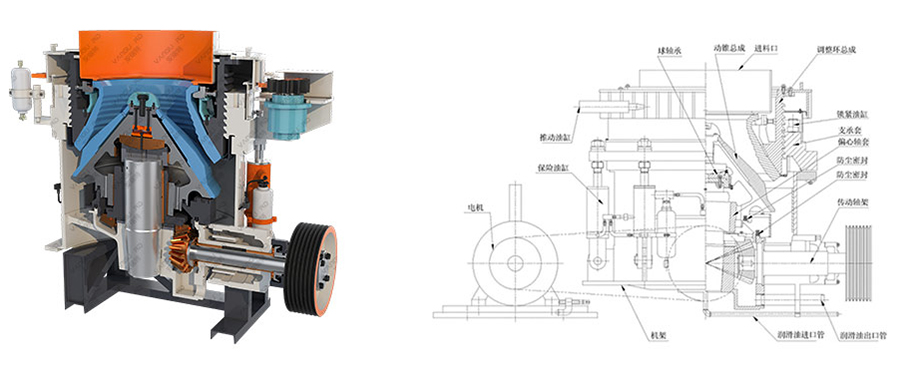

4、Cone crusher crushing method: extrusion + shear + grinding type

4、Cone crusher crushing method: extrusion + shear + grinding type

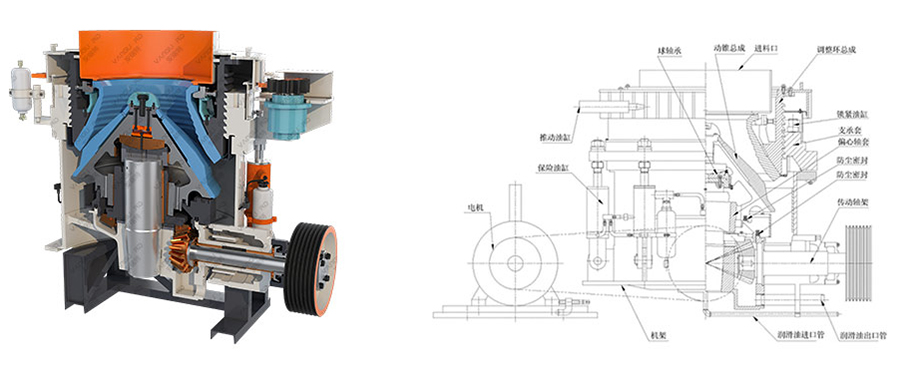

When the machine is running, the motor drives the belt wheel or coupling, and the drive shaft and cone part make the eccentric shaft do cyclic swinging movement under the axis. After the material enters the crushing chamber from the feeder, it is crushed by the mutual impact, extrusion, grinding and rubbing effect of the eccentric shaft and the concave. After repeated extrusion, impact and bending, the material crushed to the required size falls under its own gravity and is discharged from the bottom. (Take multi-cylinder as an example.)

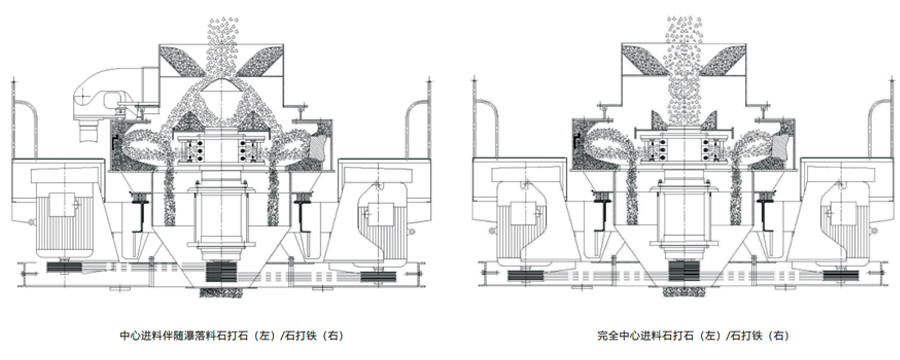

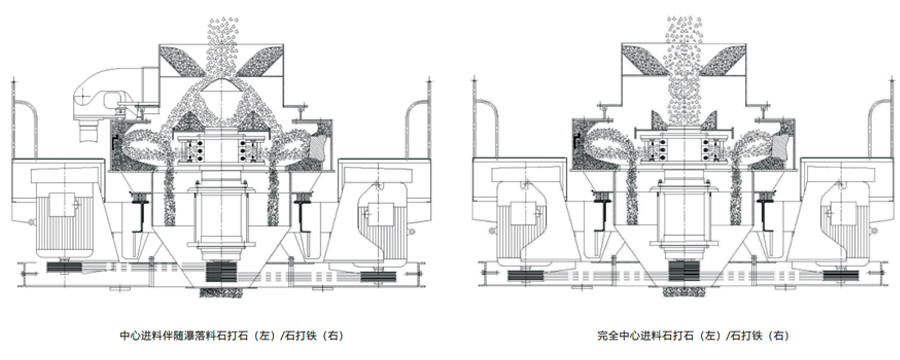

5、Impact crusher crushing method: "stone hit stone", "stone hit iron"

5、Impact crusher crushing method: "stone hit stone", "stone hit iron"

The motor drives the bearing cylinder driving part of the spindle for high-speed rotation, while the rotor will do high-speed rotational movement with the spindle, then it enters the interior of the impeller and will be sprayed into the crushing chamber after accelerated by the impeller. It collides and grinds with the lining material formed in the crushing cavity, and converts the kinetic energy obtained from the material in its accelerating process into the energy required for crushing or shaping the material. The materials that have circulated in the crushing chamber are crushed and reshaped for many times under the action of the surrounding gas vortex, so as to realize the continuous crushing and reshaping of the materials, and discharge from the lower part of the machine to form the required materials. This crushing method is called "stone hit stone", this method is mainly used for stone shaping and crushing. In addition, this equipment is also equipped with "stone hit iron" crushing method. The difference between it and the stone hit stone is that the material crushes with the impact block after it ejected from the rotor, then converting the energy obtained by accelerating the material into the energy required for collision and crushing with the impact block. After the impact, the material is directly discharged from the lower part of the machine, and it can not realize multiple cycles of crushing in the crushing chamber. This crushing method is mainly suitable for crushing-oriented working occasions (in order to provide large crushing ratio) .

Due to the different types and models of crushers, the hardness of the processed materials and the size of the output will also be different. For example, Jaw crushers are often used for primary crushing and rough crushing while impact crushers are used for secondary crushing and intermediate crushing. If your material is granite, iron ore and other hard materials, the output is 150 tons per hour, the feed size are smaller than 630mm, and the finished product is 0-20mm, you can configure a set of 4211 vibrating Feeder, a PE750*1060 jaw crusher, a 300 multi-cylinder cone crusher with a 2160 vibrating screen. If your material is limestone, the output is 600 tons per hour, feed size 800-1000mm, requires 0-6m, 6-10mm, 10-20mm finished product, you can configure a 600*160 vibrating feeder, a 6CX145 jaw crusher, four PFV1315 impact crusher with four sets of 2160 vibrating screen. (Note: This configuration is for reference only, the specific situation and machine type might be different.)

Due to the different types and models of crushers, the hardness of the processed materials and the size of the output will also be different. For example, Jaw crushers are often used for primary crushing and rough crushing while impact crushers are used for secondary crushing and intermediate crushing. If your material is granite, iron ore and other hard materials, the output is 150 tons per hour, the feed size are smaller than 630mm, and the finished product is 0-20mm, you can configure a set of 4211 vibrating Feeder, a PE750*1060 jaw crusher, a 300 multi-cylinder cone crusher with a 2160 vibrating screen. If your material is limestone, the output is 600 tons per hour, feed size 800-1000mm, requires 0-6m, 6-10mm, 10-20mm finished product, you can configure a 600*160 vibrating feeder, a 6CX145 jaw crusher, four PFV1315 impact crusher with four sets of 2160 vibrating screen. (Note: This configuration is for reference only, the specific situation and machine type might be different.)

Vanguard Machinery is a professional manufacturer in the processing of aggregate material’s production, construction sand, urban construction waste treatment and other integrated supporting equipment. We have experienced technical engineers to provide you with reasonable selection, tailor-made solutions, technical training, installation and commissioning services.

Vanguard Machinery is a professional manufacturer in the processing of aggregate material’s production, construction sand, urban construction waste treatment and other integrated supporting equipment. We have experienced technical engineers to provide you with reasonable selection, tailor-made solutions, technical training, installation and commissioning services.

First, what kinds of crushing methods are there in common stone crushers?

1、Jaw crusher crushing method: curved extrusion typeThe jaw crusher is driven by the fixed jaw and the swinging jaw to crush the stone. The motor drives the belt and the pulley, and moves the swinging jaw up and down through the eccentric shaft. When the jaw rises, the angle between the elbow plate and the jaw becomes larger, thus pushing the jaw plate closer to the fixed jaw plate, and the material is crushed or split to achieve the purpose of crushing. When the jaw goes down, the angle between the elbow plate and the jaw becomes smaller, and the jaw plate leaves the fixed jaw plate under the action of the tie rod and spring, and the crushed material is discharged from the lower mouth of the crushing chamber.

The rotor rotates at a high speed driven by the electric motor. When the material enters the flat hammer area, it crushes by the crushing the flat hammer on the rotor, then it is thrown to the counterattack device and crushed again, then it bounces back to the flat hammer area from the counterattack liner and crushes again. This process will be repeated, and the material enters the first, second and third counterattack chambers from large to small and crushes repeatedly until the material is crushed to the required size and discharged from the discharge port.

The material enters the crusher, crushes after the impact of the high speed rotating hammer head. The crushed material gets the kinetic energy from the hammer head, rushes to the baffle plate and screen bar in the frame, meanwhile the material hits each other and will be crushed several times. The material smaller than the gap of the screen bar is discharged from the gap, while the larger material is crushed again by the impact of the hammer head, grinding and squeezing on the screen bar. Then the material is extruded from the gap by the hammer head, so as to obtain the required size of the product.

When the machine is running, the motor drives the belt wheel or coupling, and the drive shaft and cone part make the eccentric shaft do cyclic swinging movement under the axis. After the material enters the crushing chamber from the feeder, it is crushed by the mutual impact, extrusion, grinding and rubbing effect of the eccentric shaft and the concave. After repeated extrusion, impact and bending, the material crushed to the required size falls under its own gravity and is discharged from the bottom. (Take multi-cylinder as an example.)

The motor drives the bearing cylinder driving part of the spindle for high-speed rotation, while the rotor will do high-speed rotational movement with the spindle, then it enters the interior of the impeller and will be sprayed into the crushing chamber after accelerated by the impeller. It collides and grinds with the lining material formed in the crushing cavity, and converts the kinetic energy obtained from the material in its accelerating process into the energy required for crushing or shaping the material. The materials that have circulated in the crushing chamber are crushed and reshaped for many times under the action of the surrounding gas vortex, so as to realize the continuous crushing and reshaping of the materials, and discharge from the lower part of the machine to form the required materials. This crushing method is called "stone hit stone", this method is mainly used for stone shaping and crushing. In addition, this equipment is also equipped with "stone hit iron" crushing method. The difference between it and the stone hit stone is that the material crushes with the impact block after it ejected from the rotor, then converting the energy obtained by accelerating the material into the energy required for collision and crushing with the impact block. After the impact, the material is directly discharged from the lower part of the machine, and it can not realize multiple cycles of crushing in the crushing chamber. This crushing method is mainly suitable for crushing-oriented working occasions (in order to provide large crushing ratio) .

Second, which crusher is good for crushing stone?

Which crusher is good for crushing stone is mainly based on the actual situation and specific needs, such as: the nature of the material, output requirements, feed size, finished product specifications, the choice of fixed or mobile type, investment budget, site size, etc.