As The Preferred Equipment For Soft Rock Crushing, What Issues Should Be Paid Attention To When Using The Impact Crusher?

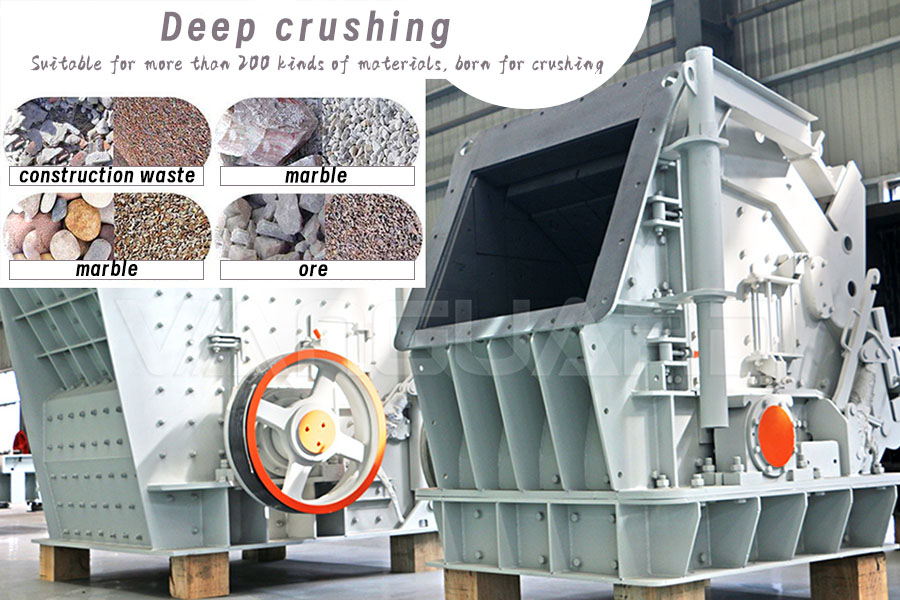

Date:2023-07-26The impact crusher is a commonly used equipment in mine crushing. It has the advantages of a large reduction ratio and a good particle shape of the finished product, which is widely used in mines, building materials, roads, railways and chemical industries. When using the impact crusher, it is necessary to pay attention to the correct operation method and safety regulations, follow the operation manual provided by the equipment manufacturer, and regularly check and maintain the equipment to ensure its normal operation and prolong its life.

The following are some suggested references for the correct operation of impact crushers:

1. Material control

(1). Reasonably control the feed

According to the specifications and requirements of the equipment, the feeding amount and speed should be reasonably controlled to ensure the reasonable control of the material and the stability of the feeding amount and avoid overloading the equipment or material accumulation caused by excessive feeding speed and avoid to cause the influence to the load of the impact crusher.

Try to control the uniform distribution of materials in the crushing cavity, avoid excessive concentration in a certain position, make the crushing more uniform, and improve the crushing efficiency and final product quality. The feeding speed can be controlled by adjusting the running speed and feeding volume of the feeding device, and the feeding speed can be precisely controlled by adjusting the parameters of the frequency converter to avoid equipment damage caused by overload operation or excessive feeding.

(2). Avoid excessive material entering the crushing chamber

Ensure that the size of the material meets the requirements of the equipment, and avoid excessive material entering the crushing chamber, so as not to cause material jams or equipment failure. For different types of materials, according to their characteristics and required crushing effects, pay attention to check the uniformity and humidity of the materials, and properly adjust the feeding amount and speed, which can improve the crushing effect and operating efficiency of the equipment.

2. Regularly check the wearing parts

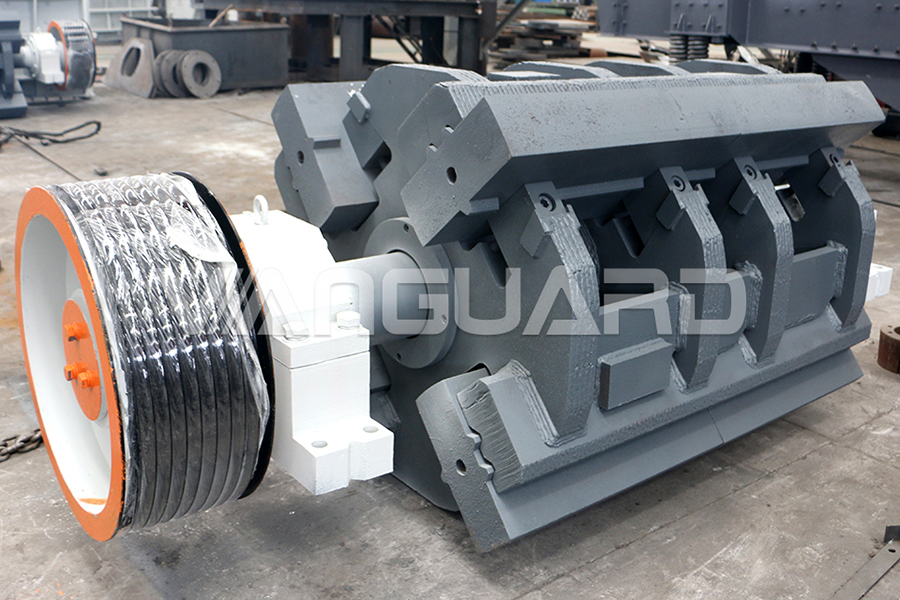

Regularly check the wear of the impact block, liner, flat hammer and other wearing parts, and replace or repair them in time to ensure the normal working condition of the equipment. It is recommended to formulate a reasonable inspection plan according to the frequency of use of the equipment and the working environment and record the maintenance situation so that necessary maintenance measures can be taken in time.

(1). Impact block and liner:

Regularly check the wear of the impact block and liner to ensure its integrity, so as to ensure the crushing effect and the smooth passage of materials. Observe whether its surface is deformed, worn or cracked. If serious wear or cracks are found, it should be replaced or repaired in time. Keeping impact blocks and liners in good condition helps maintain crushing effectiveness and equipment stability.

(2). Flat hammer:

Check the wear degree of the flat hammer and observe whether the flat hammer is blunt, severely worn or cracked. If excessive wear is found, it needs to be replaced or repaired in time. The use of a severely worn flat hammer may result in a reduction in the crushing effect and even equipment failure.

(3). Other wearing parts:

In addition to impact blocks, liners and flat hammer, other wearing parts should be checked regularly to observe their wear and operating conditions. Replace or repair if necessary.

Motor: Regularly observe the running state, temperature and noise of the motor. If found the motor is abnormal heating, noise or vibration, it should be repaired or replaced in time.

Transmission: Check the wear and fastening of the transmission (such as belts, pulleys). Ensure the normal operation of the transmission. If serious wear, looseness or damage is found, it needs to be replaced or repaired in time.

Hydraulic system: Regularly check the oil quality, leakage and pressure of the hydraulic system. Ensure the normal operation of the hydraulic system. If the oil is found to be dirty, leaked or abnormal in pressure, it should be repaired or replaced in time.

Control system: Check the electrical components, wiring and control procedures of the control system. Ensure the normal operation of the control system. If electrical faults, loose wiring, or abnormal control procedures are found, repairs or adjustments should be made in time.

3. Regular maintenance and lubrication

Regularly check the lubrication of the equipment, keep the equipment well lubricated, and regularly add or replace lubricating grease as needed to reduce friction, reduce energy consumption, and prolong the life of the equipment. The following are common lubrication points of impact crusher in general, but the lubrication points and methods of specific equipment may be different. Customers can obtain exact lubrication point locations and suggestions according to the equipment manual or contact the manufacturer. At the same time, pay attention to regular cleaning of the lubricating parts, and ensure the selection of appropriate lubricants and lubricant additions to maintain the normal operation of the equipment and prolong the service life.

(1). Main shaft bearing: The main shaft bearing in the impact crusher is an important lubricating part, which requires regular lubrication, inspection and maintenance to ensure that the grease is always in good condition and the main shaft bearing works normally.

(2). Connecting pins of the back cover: According to the requirements of the equipment, add an appropriate amount of lubricating oil to the appropriate position of the connecting pins. The lubricating oil should be evenly distributed on the connecting pins and the surrounding friction surfaces to ensure that the connecting pins can move freely and run smoothly without abnormal friction or jamming.

4. Observe the operation status of the equipment

Observing the operating status of the equipment is the key to ensuring the normal operation of the impact crusher and discovering potential problems in time. If you notice that the equipment is operating abnormally, you should stop it immediately for inspection and maintenance. The following are some equipment indicators that need to be observed.

(1). Speed: Observe whether the speed of the crusher meets the normal range. Unusually low or high speeds may indicate a malfunction or improper operation of the equipment.

(2). Vibration: Pay attention to observing the vibration of the equipment. Normal slight vibrations are normal, but excessive vibrations may indicate problems with the equipment such as imbalance, wear or looseness.

(3). Noise: Pay attention to the noise level generated by the equipment. Sudden increases in noise or unusual noises may indicate that equipment components are worn, damaged, or in need of lubrication.

(4). Temperature: Regularly check the temperature of each part of the equipment. If a spot is unusually hot, it could indicate friction, poor lubrication, or other problems.

(5). Feed and discharge conditions: Observe the smoothness and uniformity of material feed and discharge. If a blockage, poor flow, or unevenness occurs, stop the machine immediately to check the cause.

(6). Current and voltage: Regularly monitor the current and voltage of the equipment to ensure that it is within the normal working range. Unusual current or voltage fluctuations may indicate an electrical fault or power supply problem.

The above are some suggestions for the use and maintenance of the impact crusher. In actual operation, it needs to be carried out according to the specific model of the equipment and the operation manual provided by the manufacturer. Before operating the impact crusher, be sure to master the operation guide of the equipment, and operate in strict accordance with relevant safety standards and regulations.

If you encounter problems or need more technical support, you can contact Vanguard Machinery directly, and we can provide you with professional suggestions and solutions.