What is the Difference Between a Single-cylinder Cone Crusher and a Multi-cylinder Cone Crusher?

Date:2023-08-09The single-cylinder cone crusher and multi-cylinder cone crusher are two common ore-crushing equipment, which is used for fine crushing and medium crushing of ore, rock and other materials. After crushing, the final product is in the form of cubes with high fine-grain content, which can well meet the current demand for some high-quality aggregates. So, what is the difference between the two crushers? Which crusher is more suitable?

There are certain differences between the single-cylinder cone crusher and multi-cylinder cone crusher in terms of composition, working principle, wearing parts, lubrication system, crushing effect, discharge port adjustment device, actual capacity, overload protection, etc. The following is a brief introduction for your reference.

1. Differences in composition structure and principle

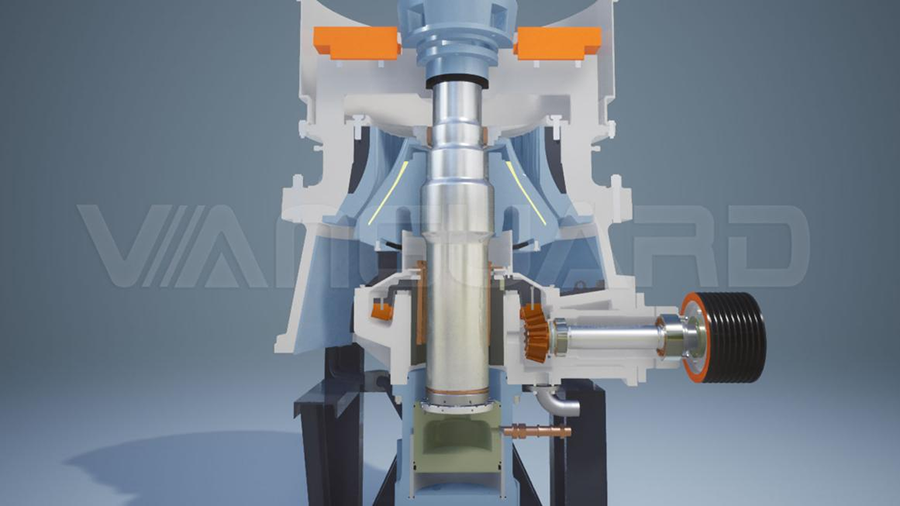

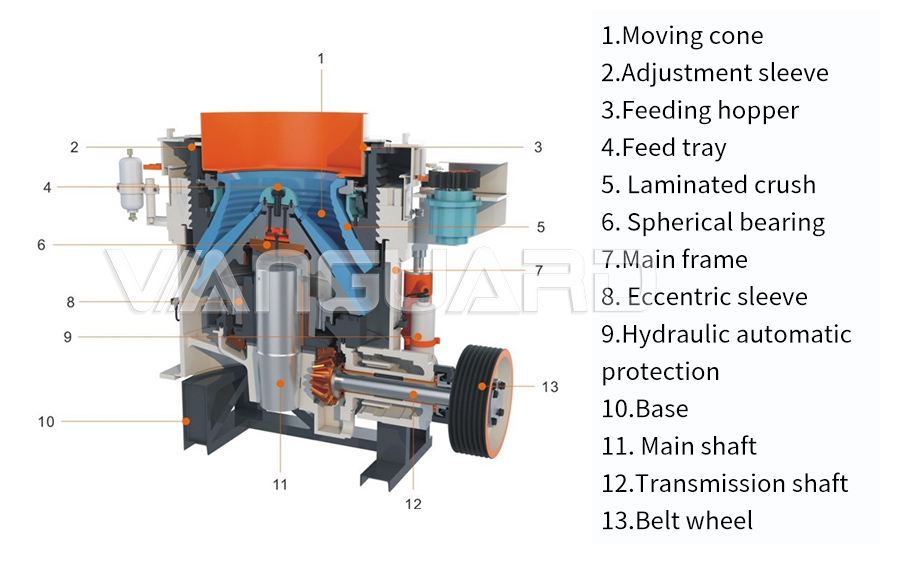

Single-cylinder cone crusher: The single-cylinder cone crusher is composed of the main shaft, eccentric sleeve, crushing cavity, adjustment device, and hydraulic station. The single-cylinder hydraulic cone crusher can adjust the hydraulic cylinder at the bottom of the moving cone to make the moving cone move up and down, so as to conveniently adjust the size of the ore discharge port and the size of the product.

Multi-cylinder cone crusher: Multi-cylinder cone crusher consists of multiple crushing cavities (usually 2-6), main shaft, adjustment device, hydraulic station, etc. When working, the motor drives the pulley or the coupling, and the drive shaft and the conical part make the eccentric shaft do periodic swinging motion under the axis line. After the material enters the crushing cavity from the feed port, it is crushed due to the mutual impact, extrusion, grinding and kneading of the eccentric shaft and the concave.

2. The difference between the lubrication system

Single-cylinder cone crusher: It usually adopts an oil lubrication system, and the lubricating oil is sent to the lubricating point through the oil pump for lubrication. Lubricating oil can enter from the lower end of the main shaft, and lubricate the spherical bearings, spherical pads, frame bushings, main shaft, bushings and bevel gears respectively. In addition, there is another way of oil injection, which is to enter from the end of the transmission shaft, lubricate the bushing of the transmission shaft, and the two oils will be discharged from the same oil outlet.

Multi-cylinder cone crusher: the lubricating oil enters from the lower part of the machine, and after reaching the middle part of the main shaft, it is divided into three branches. These branches include the inner and outer surfaces of the eccentric sleeve, the oil hole in the middle of the main shaft reaches the ball bearing, and the large and small bevel gears are lubricated through the hole. In this way, the lubricating points in different parts can be properly lubricated to better ensure the lubricating effect.

3. The difference between wearing parts

Single-cylinder cone crusher

Non-standard wearing parts: Taper sleeve, oil seal, rolling socket wall, shaft sleeve, pressure cap, cutting ring, crushing wall, dustproof ring, upper and lower friction discs, oil retaining ring, frame bushing, middle friction ring, eccentric lining set.

Multi-cylinder cone crusher

Standard wearing parts: V-belt, skeleton oil seal, O-shaped sealing ring, dust-proof ring, Yx-shaped sealing ring, Yz-shaped sealing ring.

Non-standard wearing parts: Small bevel gear, shaft sleeve, guard plate, eccentric sleeve lining, large bevel gear, upper friction disc, ball shoe, crushing cone, cone head, floating bushing, sealing ring, concave, rib pickguard.

These wearing parts may be affected by wear, impact or other factors during use, and need to be checked and replaced regularly to ensure the normal operation of the equipment and prolong its service life. Please follow the specific maintenance guidelines and recommendations provided by the manufacturer for corresponding maintenance and replacement work. At the same time, reasonable operation and maintenance can also reduce the damage of wearing parts and improve the efficiency and safety of equipment.

4. The difference between feeding and crushing effects

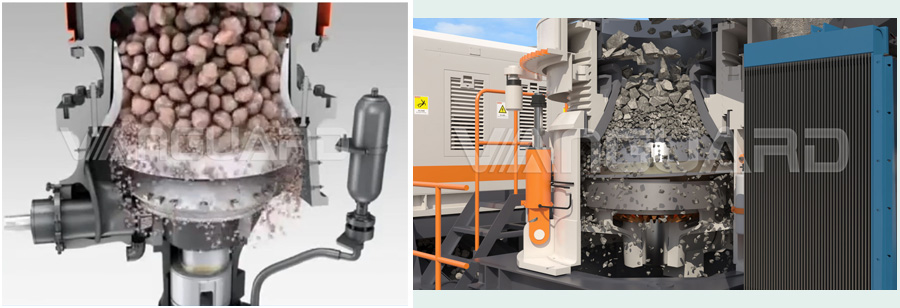

Both the single-cylinder hydraulic cone crusher and multi-cylinder hydraulic cone crusher can feed materials at full capacity. Due to their high load-bearing capacity, the multi-cylinder hydraulic cone crusher can achieve full feeding and use the principle of lamination crushing. The crushing has a shaping effect with good output particle shape at the same time.

Single-cylinder hydraulic cone crusher: It is suitable for materials with medium hardness, with a large throughput, and used for large crushing tasks, through hydraulically adjusting the size of the discharge port, it can process medium to large materials, so as to achieve better medium crushing effect.

Multi-cylinder hydraulic cone crusher: It is suitable for materials with higher hardness with a more detailed crushing process and higher crushing efficiency, The content of fine-grained materials under the fine crushing discharge port is high with better effect of fine-grained and laminated, and the high fine-grained level of the final product and the more uniform product particle size.

5. Difference capacity

When crushing soft ore and weathered ore, the single-cylinder hydraulic cone crusher has the advantage of large throughput. When crushing medium-hard and high-hard ore, the multi-cylinder hydraulic cone crusher is more suitable.

In general, the multi-cylinder cone crusher has greater capacity than the single-cylinder cone crusher. This is because the multi-cylinder cone crusher adopts multiple independent crushing cavities, and each crushing cavity can perform independent crushing operations to achieve multi-stage crushing, thereby increasing the processing capacity and output.

It should be noted that the specific capacity difference is also affected by many factors, such as material hardness, humidity, feeding method, equipment parameters, etc. Different process requirements and material characteristics will also have an impact on capacity.

To sum up, there are some differences between the single-cylinder hydraulic cone crusher and multi-cylinder hydraulic cone crusher in terms of structure, adjustment device, lubrication system, wearing parts, crushing effect and capacity. When selecting a cone crusher, it should be determined according to specific needs, comprehensively considering factors such as material characteristics, capacity requirements, production scale and particle size requirements, and choosing the appropriate model and configuration to meet production needs.