What Are The Common Ways To Adjust The Discharge Port Of The Jaw Crusher?

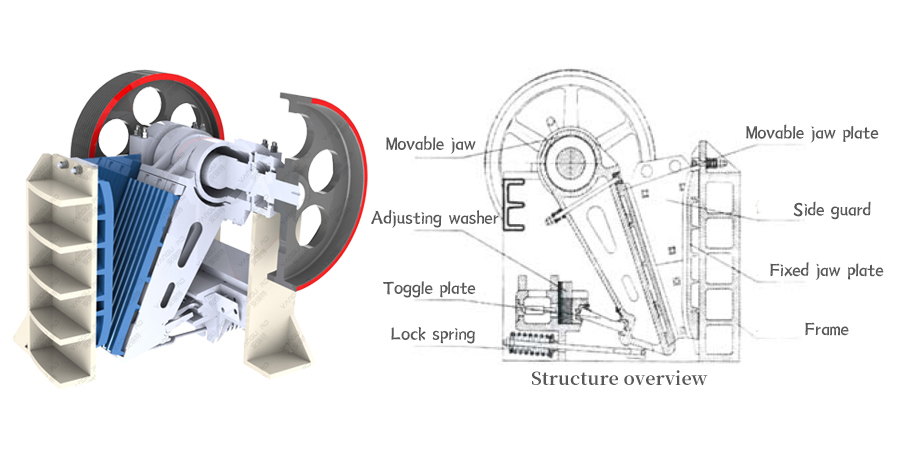

Date:2023-08-17The size of the discharge port of the jaw crusher determines the particle size of the crushed ore and the production capacity of the equipment. Therefore, in practical applications, according to the requirements of the ore and the performance of the equipment, it is necessary to select a suitable discharge opening size to meet the requirements of the equipment. The required particle size and production capacity requirements. Meanwhile, it is necessary to adjust the discharge port according to different crushing requirements, so as to meet the crushing requirements in different situations and avoid affecting the crushing efficiency and output of the crusher due to too large or too small discharge port.

Common jaw crusher discharge port adjustment methods include backing plate adjustment, wedge block adjustment and hydraulic cylinder adjustment.

1. Backing plate adjustment

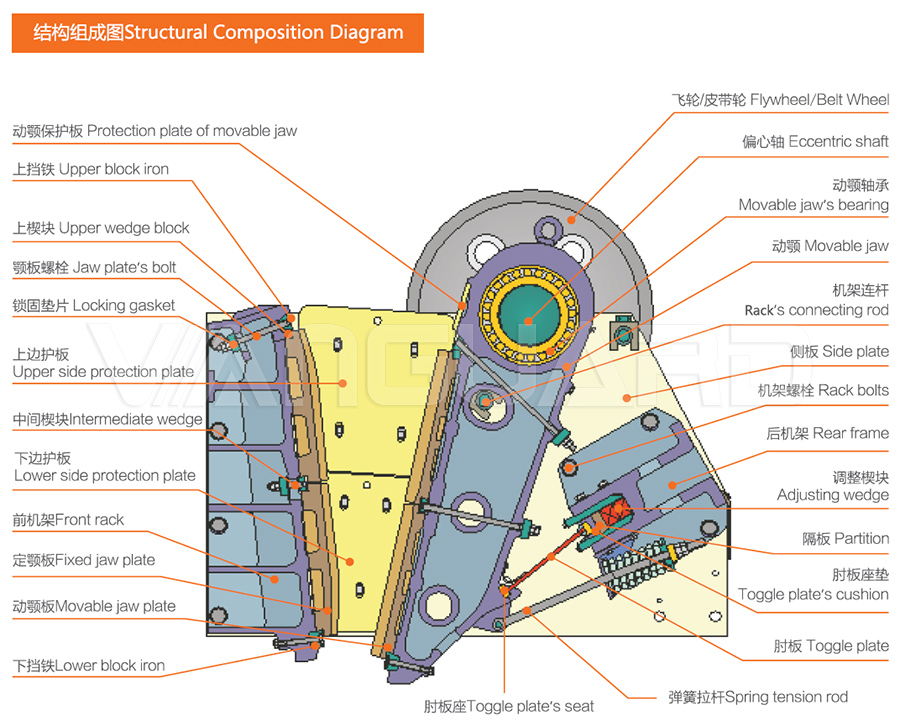

By adjusting the quantity and total thickness of the backing plate to change the size of the discharge port, so as to achieve a better crushing effect. The jaw crusher's toggle plate seat is behind the adjustment seat and is usually made of wear-resistant materials. The pad is placed at the bottom of the discharge port and is fixed in the crushing cavity. Generally, a thicker backing plate can narrow the discharge port, resulting in smaller particle sizes. While a thinner backing plate can widen the discharge port, so as to obtain a larger material particle size.

The advantage of backing plate adjustment is that the operation is relatively simple. During the adjustment process, the equipment usually needs to be shut down and safe operation should be ensured to avoid potential dangers. In addition, backing plate adjustment can also be fine-tuned as needed to meet the particle size requirements for crushing tasks.

It should be noted that backing plate adjustment is a manual adjustment method that may require certain experience and skills. It is recommended to understand the operation manual and relevant safety regulations of the equipment in detail before adjusting the backing plate and follow the manufacturer's instructions to ensure correct operation and ensure personnel safety.

2. Wedge block adjustment

The wedge block adjustment device consists of two identical wedge blocks, usually made of wear-resistant materials, shaped like wedges. These two wedge blocks are located behind the toggle plate's seat in the adjustment seat, and their inclined surfaces are fitted together. By changing the relative position of the two wedge blocks, the total thickness of the wedge block pair can be changed. In this way, the position of the toggle plate will also change, which will in turn move the position of the jaw and realize the adjustment of the size of the discharge port.

This wedge block adjustment device has a large adjustment range and high precision, which can meet the requirements of different crushing tasks for the particle size of the discharge port. This adjustment method is relatively simple, has high flexibility, and can be adjusted in real-time during the production process. During adjustment, it is usually necessary to stop the machine and take necessary safety measures. In addition, regularly check the wear of the wedge block and replace or repair it as necessary to ensure the normal operation of the adjustment device and the performance of the equipment.

3. Hydraulic cylinder adjustment

Hydraulic cylinder adjustment is a common way of adjustment, which changes the position of the moving jaw by adjusting the hydraulic cylinder in the middle of the toggle plate, thereby changing the opening size of the discharge port and controlling the discharge size of the crusher.

This hydraulic cylinder adjustment features a wide adjustment range, fast response speed, and easy operation. It can also be used for iron removal and cleaning, improving the convenience of operation while reducing worker fatigue. By adjusting the oil pressure and flow in the hydraulic system, the opening size of the discharge port can be precisely controlled to meet the particle size requirements of different materials.

It should be noted that during hydraulic cylinder adjustment, it is necessary to ensure the normal operation of the hydraulic system and follow the corresponding safety operation procedures. Regularly check the sealing performance of the hydraulic cylinder and perform maintenance to ensure its reliability and stability. Compared to traditional manual or mechanical adjustment methods, this hydraulic oil cylinder discharge port adjusting device has higher manufacturing costs.

Therefore, the pad type and wedge type are currently the most commonly used methods for adjusting the discharge port of jaw crushers. These two methods are relatively simple, low cost, and to a certain extent, meet the needs of discharge port adjustment. The hydraulic cylinder adjustment device has greater flexibility and precision in functionality and performance, with stronger adaptability. However, it has a higher cost and requires advanced operation and maintenance skills. In practical application, it is necessary to comprehensively consider the selection of the appropriate discharge port adjustment method based on specific conditions (such as budget, production requirements, etc.).