Which Parts of the impact Sand Making Machine Need to be Replaced Frequently?

Date:2023-10-26The sand making machine is suitable for medium and fine crushing various ores and rocks with different hardness levels, providing advantages such as high production efficiency, large reduction ratio, good quality of the final crushed sand, and uniform particle size. It is widely used in industries such as construction, highways, railways, water conservancy, and chemical industry. When using the sand making machine, it is necessary to pay attention to safe operation and follow the instructions and maintenance regulations of the equipment. Regularly inspect and maintain the sand making machine to ensure the normal operation and service life of the equipment. In addition, choosing the type and configuration of the sand making machine reasonably can also improve production efficiency and sand quality.

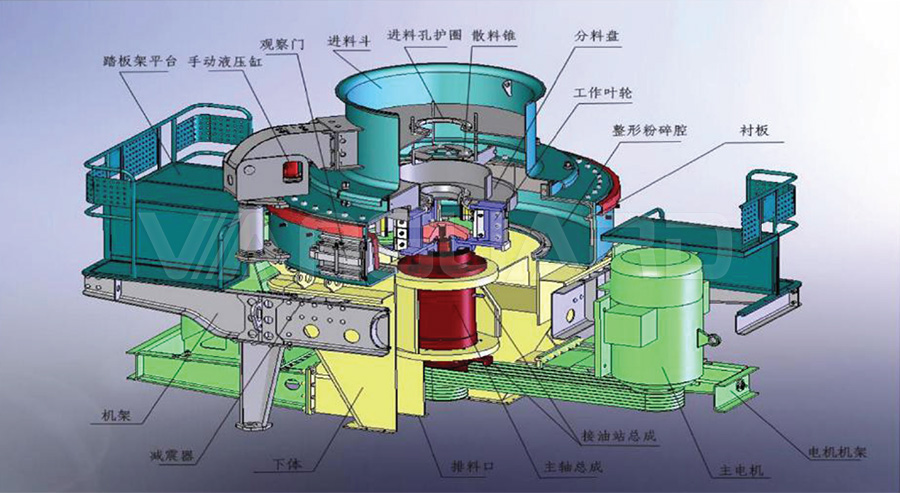

The following components of the impact sand making machine may need to be replaced frequently during use:

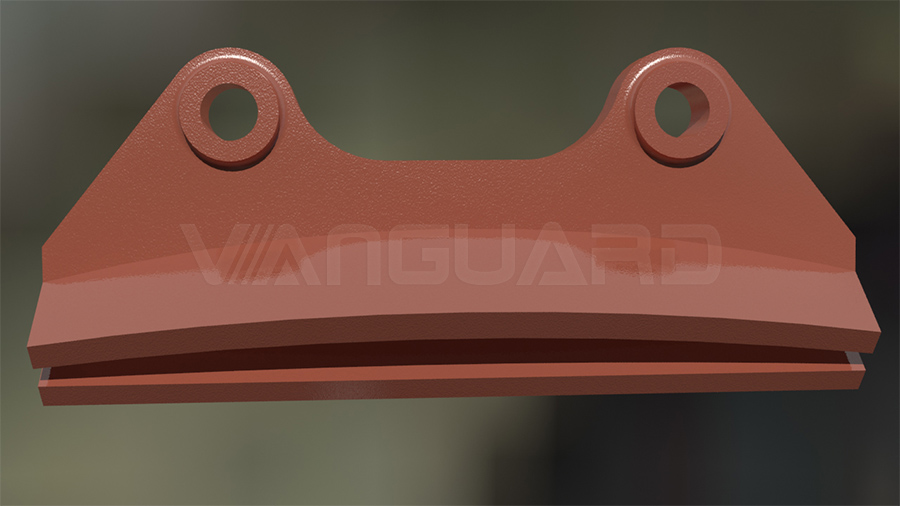

1. Throwing head: The throwing head is located on the rotor of the impact sand making machine and is usually made of wear-resistant alloy material. The throwing head rotates at high speed, collides with the feed material and generates impact on the force. Therefore, it is necessary to frequently check and replace worn or damaged ejection heads during use.

2. Impeller: The impact block is fixed on the crushing plate of the impeller, typically made of wear-resistant materials, and has strong impact resistance and wear resistance. When the raw material passes through the crushing cavity, the impact blocks are crushed by the impact force. During long-term use, the impact block will lose its crushing ability due to wear and tear, therefore it is necessary to timely replace the worn impact block to ensure the normal operation of the sand making machine.

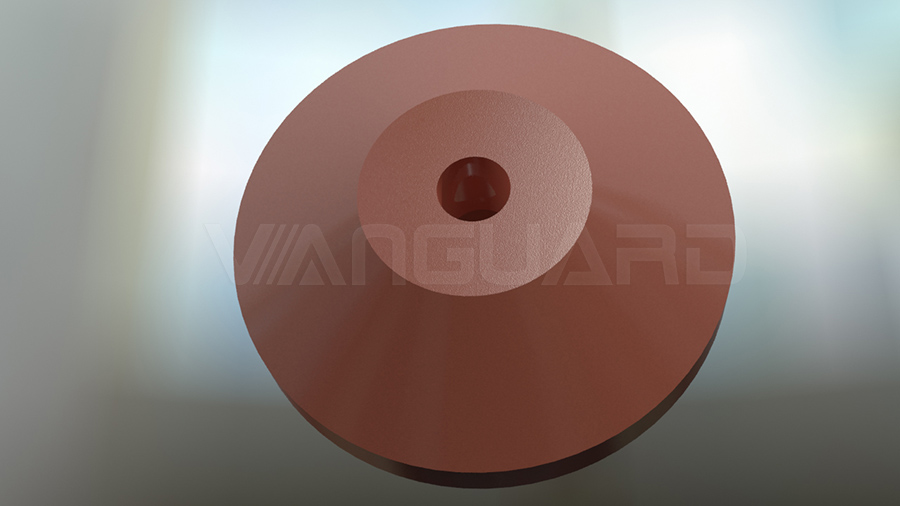

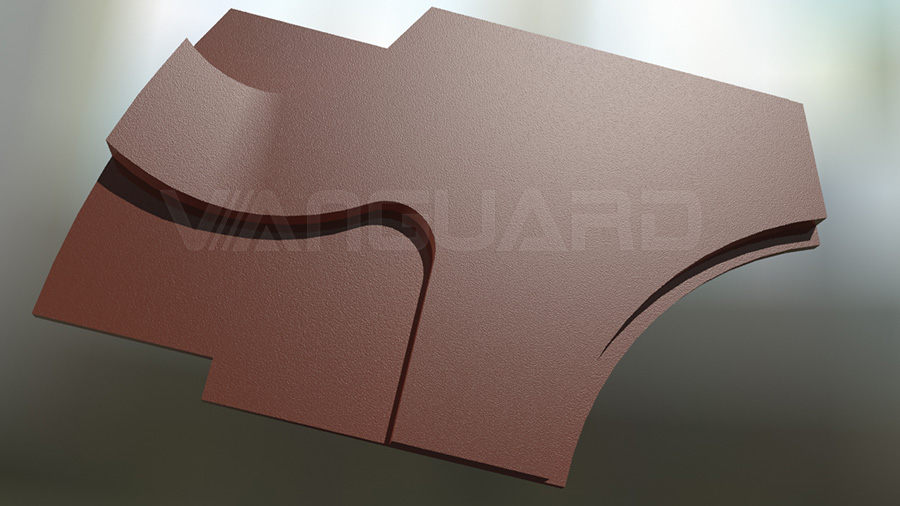

3. Distributing tray: The distribution tray is usually located above the feed port of the impact sand making machine. Its function is to evenly disperse the feed material into the crushing cavity. The design of the material distributing tray can adjust the distribution and flow rate of the feed to ensure that the materials are evenly impacted and broken in the crushing cavity. The distributing tray needs to be adjusted and maintained according to the nature of the material and feeding requirements to ensure a good crushing effect.

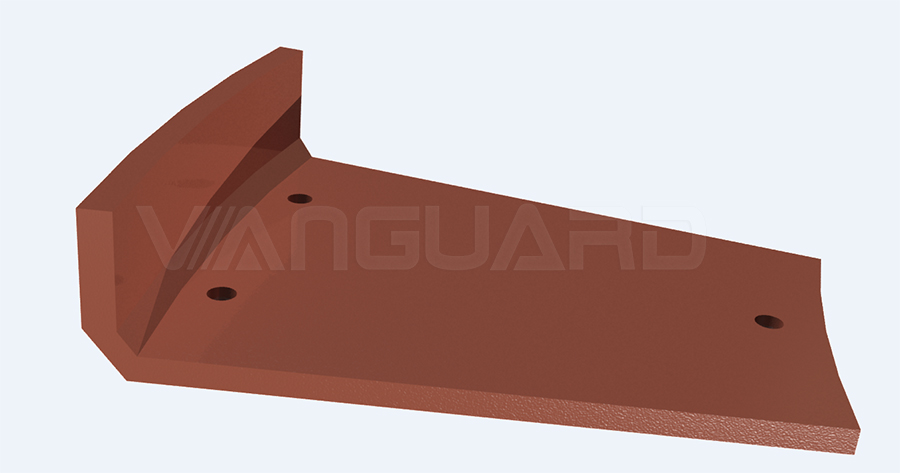

4. Flow plate: The flow plate is located in the upper and lower parts of the impeller, and plays a role in guiding and protecting the material when it passes through the crushing cavity. The design of the flow plate can control the flow route of the material and avoid excessive crushing or blockage. Due to the impact and wear of materials, the flow channel plate is susceptible to wear and tear, so the worn flow channel plate needs to be checked and replaced regularly to ensure the stable operation and effective crushing of the sand making machine.

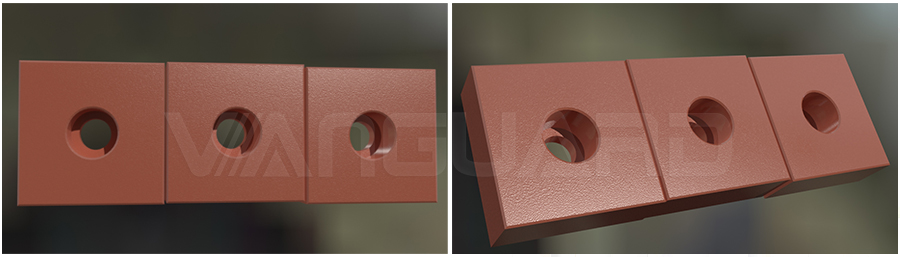

5. Peripheral protective plate: The peripheral protective plate is usually fixed on the crushing cavity wall of the impact sand making machine, which can protect the crushing cavity wall, reduce direct impact and wear, and extend the service life of the crushing cavity wall. The design of the surrounding guard plate can affect the flow and collision mode of materials in the crushing cavity, thereby improving the crushing effect of materials and increasing crushing efficiency and capacity. Because the peripheral protective plate is inside the impact sand making machine, it is easily affected by the impact and wear of materials. Therefore, it is necessary to regularly check the wear of the peripheral protective plate and replace worn parts in time to maintain the normal operation and crushing effect of the sand making machine.

When using the impact sand making machine, the operator can understand the equipment operation and maintenance methods and replacement cycle according to the guidance and equipment maintenance manual provided by the manufacturer, ensure the uniform feeding of materials and the normal operation of the crushing cavity, and improve the efficiency of the sand making machine. Production efficiency and sand quality. Under normal circumstances, the replacement cycle of the ejection head and impact block of the sand making machine is generally more than half a month. The distribution tray and flow channel plate are used for a long time, which is 2-3 times that of the ejection head and impact block. The board replacement cycle is approximately one year.

When using an impact sand making machine, follow the operating manual and manufacturer's recommendations to ensure the safe operation of the equipment and operator safety. Here are some common considerations:

1. Follow the operation manual: Before the operation, carefully read and understand the operation manual of the impact sand making machine, and operate the equipment correctly according to the requirements. Do not modify or ignore the operating steps without authorization.

2. Connect the power supply correctly: Ensure that the power supply wiring of the device is correct, the voltage is stable, and the grounding is reliable to prevent electrical faults and the risk of electric shock.

3. Check the wearing parts: Before use, check and maintain the wearing parts of the impact sand making machine to ensure that they are in good working condition.

4. Smooth feeding: When feeding the impact sand making machine, the feeding should be kept even and continuous to avoid overloading to avoid equipment damage or blockage.

5. Pay attention to safety protection: During use, operators should correctly wear personal protective equipment such as safety helmets, work clothes, and protective glasses to prevent dust, splashes, or other hazards from harming personal safety.

6. Regular inspection and maintenance: Regularly inspect key components of the equipment, such as motors, belt drives, bearings, etc., and perform timely maintenance and replacement to ensure the reliability and stability of the equipment.

7. Cut off power before shutting down: Before performing equipment maintenance, cleaning or shutdown adjustments, be sure to disconnect the power supply and take appropriate measures to prevent misoperation or accidental injury.

Vanguard Machinery has won the trust of customers with its exquisite craftsmanship, excellent quality and perfect after-sales service. Since its establishment, Vanguard Machinery has been committed to developing and producing high-quality mechanical equipment to promote the sustainable development of the mining industry. It has also shown a high degree of professionalism in the maintenance and upkeep of equipment. The company provides customers with Comprehensive maintenance and upkeep solutions, Vanguard Machinery also provides customers with professional technical support to help customers solve problems encountered during use.