Differences and Purchasing Guide Between Stationary, Mobile and Semi-mobile Crushing Production Lines!

Date:2023-11-16In mining, crushing equipment has a wide range of applications and plays an important role in the processing and handling of various ores. By crushing different types of ores, the needs of various major industrial fields can be met. Different types of ores require different crushing processes and equipment. Therefore, it is necessary to comprehensively consider factors such as process requirements, equipment parameters, and quality requirements according to the actual situation to select appropriate crushing equipment. Crushing equipment can be divided into three types: stationary, mobile and semi-mobile crusher. This article will elaborate on these three types of crushing equipment and analyze their differences.

1. Stationary crushing equipment:

Stationary crushing equipment requires the construction of a foundation, with large civil and labor investments. These infrastructures are usually designed and constructed based on the size, weight, and production capacity of the equipment. The requirements for site selection are relatively high, and the site needs to be fully utilized. Once the site needs to be moved to another location, the original infrastructure usually needs to be dismantled and rebuilt.

Stationary crushing equipment is usually used together with feeders, crushers, vibrating screens, conveyors and other equipment to form a production line to form a complete production system. Such a production line can be configured and adjusted according to specific material crushing requirements and process flow. To achieve efficient crushing and screening operations.

2. Mobile crushing plant:

Mobile crushing plant is divided into tire-type mobile crushing plant and crawler-type mobile crushing plant. The tire-type mobile crushing plant relies on the front of a semi-trailer for traction, while the crawler-type mobile crushing plant adopts a self-driven mode, which can realize on-site steering and can be driven to a destination through wireless remote control. on a trailer for quick transitions. The mobile crushing plant does not require the construction of a factory building or civil foundation, which reduces the investment and time of project construction. It also avoids material transfer and reduces transportation costs, and the construction period is short.

The mobile crushing plant breaks through the limitations of site, environment, basic configuration and logistics. It can operate independently as a single unit and can be combined with different models to form a powerful crushing operation assembly line to complete processing operations with multiple needs and improve overall work efficiency. The mobile crushing plant can configure jaw crusher series, cone crusher series, impact crusher series, sand making machine and other crushers according to the customer's material type and product requirements in the process, providing more flexible process configurations to meet users' mobile crushing, mobile screening and other various needs.

3. Semi-mobile crushing plant:

The semi-mobile crushing plant itself does not have the function of traveling and needs to rely on external equipment, such as trailers or cranes, so it can be relocated and transferred quickly. The semi-mobile crushing plant does not require tedious civil construction work, thus saving a lot of time and cost, shortening the project cycle and improving overall efficiency.

The semi-mobile crushing plant is a multi-dimensional integrated frame structure solution composed of one or several crushing and screening unit modules. It is a semi-mobile frame structure mobile crushing plant mainly used in the primary and secondary crushing and screening stages of medium and soft hard rocks, construction waste, concrete blocks and other raw materials. It can be widely used in urban construction waste treatment, mining and tunnel construction rock crushing.

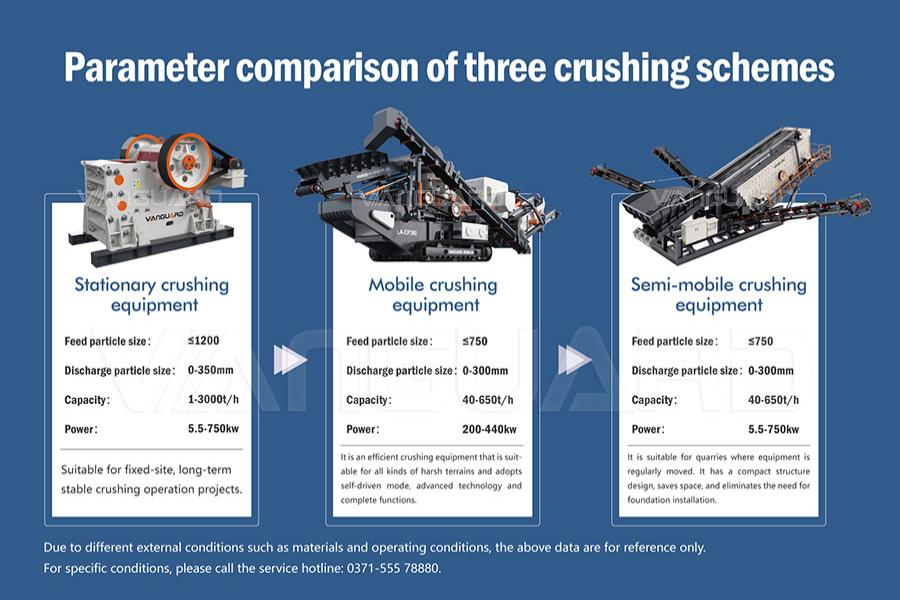

4. The difference between feed size and capacity

5. Equipment purchase suggestions:

Determine usage scenarios and needs: Consider factors such as the type of materials that need to be processed, processing volume, working hours, production requirements and budget.

Define equipment specifications: Understand the parameter information of the equipment, including motor power, speed, number of strokes, and parameters such as rotor diameter, speed, and crushing cavity type of the crusher, and determine appropriate equipment specifications and processing capabilities.

Consider mobility requirements: If frequent transfers or temporary work are required, choose a mobile crushing plant or semi-mobile crushing plant; If long-term stable operation is required, choose stationary crushing equipment.

Understand the manufacturer and service: Understand the manufacturer's reputation and after-sales service. A good manufacturer should provide comprehensive technical support and after-sales service to ensure the normal operation and maintenance of the equipment.

Consider cost-effectiveness: Comprehensively consider factors such as equipment price, operating costs, maintenance costs, and service life to ensure that the equipment can achieve a win-win cost-effectiveness in the long term.

When selecting the type of crushing equipment, factors such as material type, production needs, budget constraints, frequency of site transfers, and the cost and workload of infrastructure construction and dismantling need to be considered. If you still don't know how to choose equipment, you can consult Vanguard Machinery's engineers. The engineers will tailor a plan for you to help you make a reasonable selection.