4 Kinds of Common Hoppers were Introduced in the Gravel Production Line

Date:2023-12-13In the stone production line, the hopper is an essential part that cannot be ignored. It serves the functions of feeding, transferring, buffering, and regulating. It is because of the presence of a hopper that the crushing equipment can continuously, evenly, and smoothly feed, ensuring the production process to proceed in an orderly and stable manner.

There are various types of hoppers in the stone production line. This article provides a detailed introduction to the functions and styles of four common hoppers: raw material hopper, transfer hopper, cone crusher stable material hopper, and final product hopper. This information is for reference only.

1. Raw material hopper

The raw material hopper is in the shape of a square cone and is sealed all around. It is welded with steel plates and is usually used in front of the feeder.

The raw material hopper is commonly located above ground level, utilizing the height difference in terrain to provide gravitational potential energy to the raw material, making it convenient for the feeding of large pieces of stone. However, it is necessary to utilize the landform to form a high material platform to facilitate the entry of raw materials.

Design requirements:

(1) The capacity of the hopper should be comprehensively considered based on factors such as the specifications of the crusher, the vehicle type for transporting ore, loading capacity, and intermittent incoming trucks. Its effective volume should not be less than the capacity of the crusher when it operates continuously for 15 to 20 minutes.

(2) There is a vehicle stop on the feeding side of the silo. The height and width of the vehicle stop should be such that all the ores can fall into the feeding hopper while ensuring the safety of unloading. The height is generally 500 mm.

(3) Steel plates need to be laid on the top and both sides of the vehicle stop to prevent it from being damaged by the mine car.

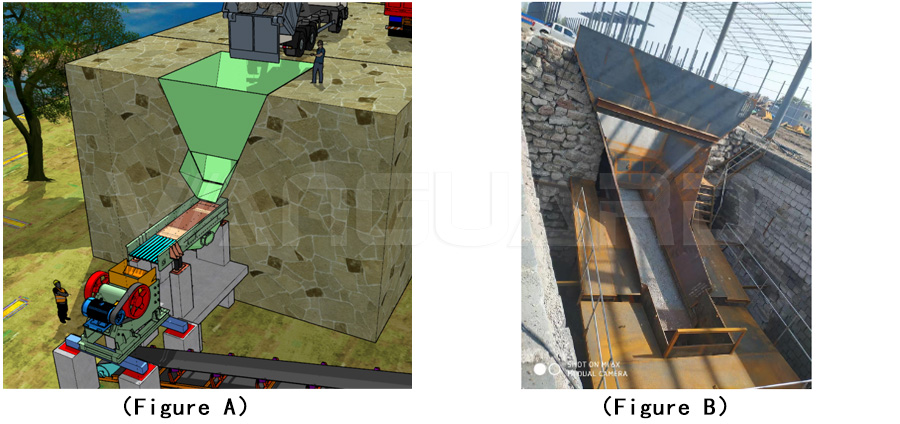

(4) The conventional opening shape of the front wall of the hopper is rectangular, but the dead corners on both sides of the rectangular opening can easily cause material blocking. The opening can also be made into a trapezoid, which can effectively prevent material blocking as shown in Figure A. In addition, as shown in Figure B, there are openings below and in front of the hopper, so there will be no material blocking. However, the disadvantage is that the feeder has to go deep into the bottom part of the hopper, making it difficult to install the feeder. Moreover, the outlet of the silo is facing the feeder. It will cause a certain amount of warehouse pressure on the feeder.

2. Transfer hopper

The transfer hopper is used for transfer and adjustment. It is made of steel structure or reinforced concrete. It is located behind the crushing module. It is generally used to store the discharged materials of the jaw crusher and then enter the intermediate crushing link after transfer. Sometimes due to site constraints, coarse crushing, medium crushing, and fine crushing are all together, and a transfer hopper is also required. The size of the hopper should generally be enough to stack aggregates for the crushing equipment to run for 2 to 3 hours. The transfer hopper is divided into a ground transfer hopper and an above-ground high-level steel structure hopper. As shown below.

3. Stable material hopper

The function of the stable material hopper is mainly to play a buffering role, such as before the cone crusher. The cone crusher requires the feeding state to be full of material, which can form effective material layer protection, protect the concave, and at the same time play the role of lamination crushing. A stable material hopper can ensure a buffer time during an emergency shutdown. In addition, when there are multiple devices in one module, it is not necessary to carry many belts but to distribute them evenly to all the devices under the hopper through one hopper. As shown below.

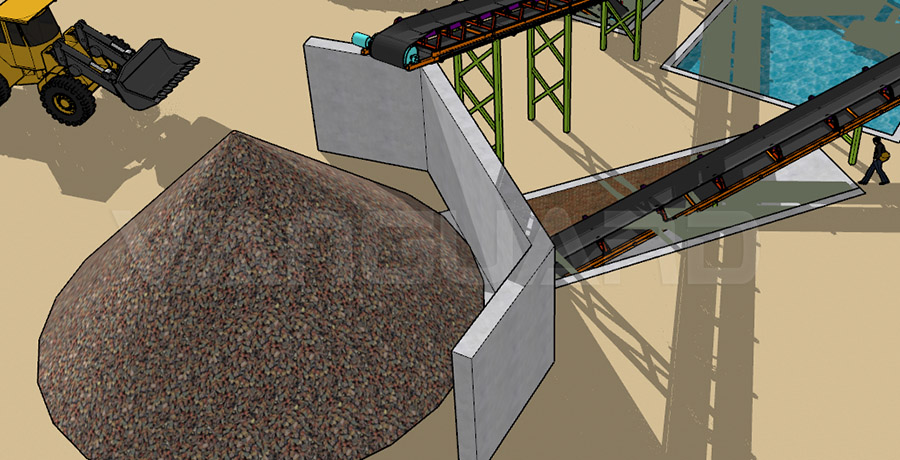

4. Final product hopper

The style of the final product hopper is mostly stacked with rectangular walls, and high concrete partitions are used to separate different product rooms (some companies also choose steel plate hoppers to store sand and gravel materials, and the wear of the steel plate warehouse needs to be checked regularly and treated with wear resistance), the products are sent to the corresponding product rooms through belt conveyors to achieve the purpose of grading products. In addition, the hardened space used for loading in the final product hopper should be enlarged as much as possible to facilitate the loading operation, while leaving sufficient buffer area for the stacking area.

The above four types of silos are the more common types of silos in gravel production lines. Specific hoppers can also be designed and configured according to different production capacities and plans, mainly from the shape, discharge port size, bucket capacity, feeding skewness, height, diameter of the hopper, and the hopper inlet are reasonably designed to ensure smooth and continuous operation of the entire gravel production line.