Common Faults and Solutions of Sand Washing Machines

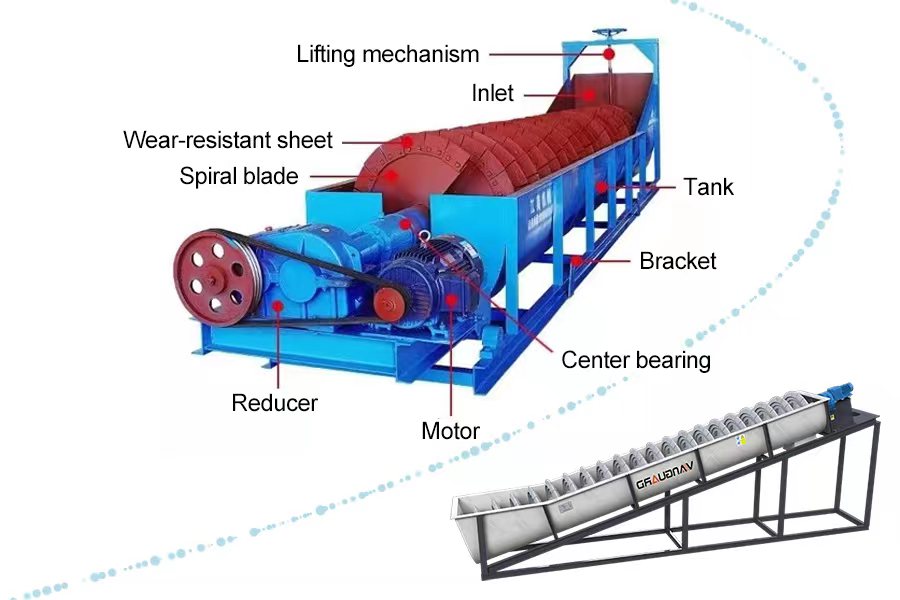

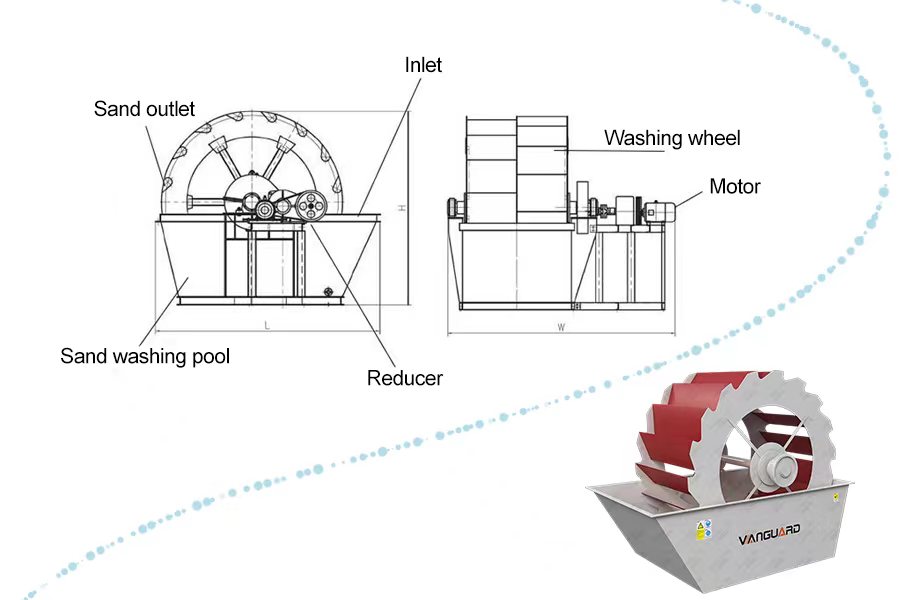

Date:2024-07-26Sand washing machines are equipment for washing machine-made sand and natural sand. There are two types of sand washing machines: spiral sand washing machines and wheel sand washing machines. They can remove impurities covering the surface of sand and gravel, and at the same time destroy the water vapor layer covering the sand particles, playing a role in efficient cleaning. In production, sand washing machines will inevitably encounter various problems.

1. The machine cannot start

Failure causes: 1) Insufficient voltage; 2) Belt slippage; 3) Reducer failure; 4) Motor damage.

Solution: 1) Change voltage supply; 2) Tighten belt strip; 3) Repair reducer; 4) Replace motor operation.

2. The machine is noisy

Failure causes: 1) Bearing damage; 2) Reducer failure; 3) The wheel bucket body rubs against the shell.

Solution: 1) Replace bearing; 2) Repair reducer; 3) Repair and adjust the wheel bucket body.

3. Too high bearing temperature

Failure causes: 1) Dirty grease; 2) Improper grease dosage; 3) Bearing damage (usually the first two reasons).

Solution: 1) Replace grease; 2) The amount of grease must be moderate, not too much or too little; 3) Replace the bearing.

4. Flipping occurs during sand washing

Failure causes: 1) The too high speed of the spiral sand washing machine; 2) The horizontal axis of the spiral disk is not fixed properly.

Solution: 1) Adjust the speed; 2) If the speed is adjusted in place and there is still flipping, fix the horizontal axis.

5. Frame vibration

Failure causes: 1) Loose bolts of the connecting frame; 2) Loose bolts of the bearing seat.

Solution: 1) Tighten the bolts; 2) Check and tighten the bolts.

6. The transmission part is noisy

Failure causes: 1) Insufficient gear lubrication; 2) Gear spacing changes

Solution: 1) Add enough grease; 2) Adjust the reducer anchor bolts and tighten them.

7. Blocked discharge port

Failure causes: This is the most common problem in the operation of the sand washer. Most of the reasons are that the sand and gravel particles in the slurry of the sand washer are too fine, and the single feeding amount is suddenly increased, resulting in the siltation of materials at the discharge port.

Solution: First, stop feeding, open all discharge ports to avoid siltation, and clean the sand washer with clean water before operation.

8. Reduced sand washing volume or sand leakage

Failure causes: 1) Sand net is damaged; 2) Sand net fixing bolts fall off.

Solution: 1) Check and repair or replace the sand net; 2) Tighten the bolts.