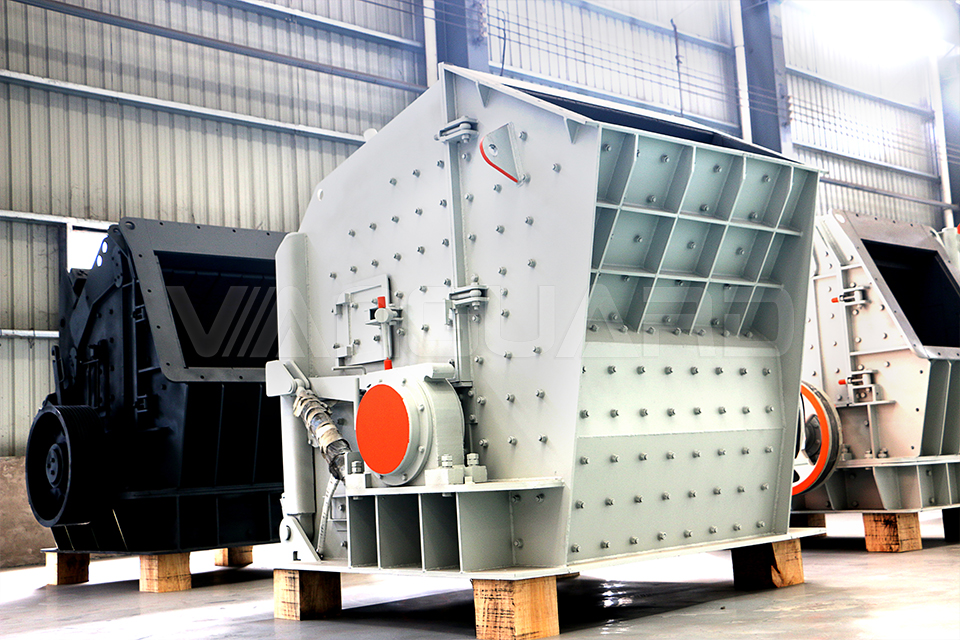

What are the Factors that Affect the Crushing Effect of Impact Crusher?

Date:2024-07-26Impact crusher is widely used in building materials, highways, railways, mining and other industries due to its simple structure and large reduction ratio. Its crushing effect has also attracted the attention of many users. What factors are related to needle-shaped finished products or round particles? How do we increase the round particle type of finished products in the impact crusher? Today we will discuss the factors that affect the crushing effect of impact crusher.

1. Rotor rotation speed

The rotor rotation speed can guide the impact crusher to select the appropriate rotation speed when crushing materials of different particle sizes and materials, thereby preventing the material from being over-crushed, and also helping to reduce energy consumption.

Effect: Generally speaking, the higher the rotor speed, the greater the impact force when the flat hammer contacts and collides with the material. As the speed increases, the greater the impact force when the material collides with the impact plate, the better the material impact crushing effect, and the higher the degree of material damage.

2. Rotor moment of inertia

Usually, each type of impact crusher can crush a certain range of materials, which is largely related to the moment of inertia of the rotor installed on the crusher. Under the same rotor speed, the rotors with different moments of inertia can provide different crushing forces, that is, different crushing capacities, which directly affect the performance of the crusher.

Effect: When the material is impact crushed, at the same speed, the greater the rotor moment of inertia, the greater the impact crushing force of the flat hammer on the material and the material and the impact plate. When the material is subsequently sheared and crushed, the smaller the reaction force of the impact plate on the material, the easier it is for the material to be sheared and crushed.

3. Angles of impact plates at all levels

The angles of impact plates at all levels have a great influence on the effective crushing force generated when stones hit the impact plates. The force perpendicular to the collision contact interface is usually called the effective crushing force, that is, the force that can cause stone crushing. The ideal situation is that the stone can be perpendicular to the impact plate every time it collides with the impact plate. At the same time, the impact plates at different angles have a great influence on the impact, shear crushing effect of the material.

Effect: The study found that reducing the angle of the first-level impact plate has a better shear crushing effect on the material, but is not conducive to the impact crushing of the material. Increasing the angle of the first-level impact plate can increase the number of impact collisions and enhance the impact crushing effect, but is not conducive to the shear crushing of the material. The same is true for the second or third-level impact plates.

The higher the rotor speed, the greater the moment of inertia, the greater the impact force, the better the material impact crushing effect, the greater the degree of material damage, and the smaller the interaction force between the material and the impact plate and hammer when shearing and crushing occurs. Reducing the impact plate angle has a better shearing crushing effect on the material, but is not conducive to the impact crushing of the material. Increasing the impact plate angle is just the opposite. These have a positive guiding role in the design, production and use of impact crushers.