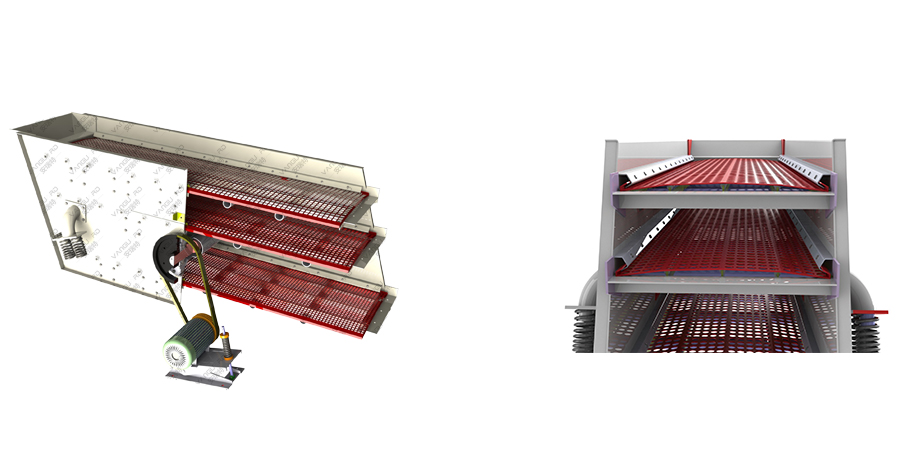

The Screen Life of the Vibrating Screen is too Short? Common Misunderstandings

Date:2024-09-13The rapid damage of the screen is one of the common problems of vibrating screens. What are the reasons that shorten its life? The main reasons include clay accumulation, wrong motor rotation, loose fit between the screen and the screen frame, and poor screen quality. Let's explain them further.

1. Clay accumulation

If the vibrating screen has too small of vibration amplitude, it cannot effectively overcome the clay's viscosity force, causing it to accumulate on the screen and quickly damage it.

Solution

1) Increase the vibration amplitude;

2) Use spray water to flush the screen and clay to reduce viscosity, but this method is only suitable for occasions where water can be added;

3) Adjust the screen angle at the sand discharge port downward to facilitate the discharge of materials by gravity;

4) Change the mesh size of the screen or adjust the flow rate of a single screen to allow the material to be discharged smoothly.

2. Wrong motor direction

When debugging the motor direction, the on-site operator believes that as long as the material moves forward, it will be fine based on experience. However, this method is only applicable to single-axis vibrating screens or linear screens and is not suitable for translational elliptical vibrating screens. If the motor rotates inward by mistake, the ejection angle is also 45° forward, but the material has the force to roll backward. At this time, the forward movement speed is much slower, and the material stays on the screen for a long time, which may even lead to the inability to discharge.

Solution

1) When the screen box is running, press the stop button of the electric control box. The vibrating screen will slowly stop. Observe the elliptical trajectory formed by the small dots on the side panel when the vibrating screen is running. The correct direction is when it rolls toward the sand outlet.

2) Remove the vibrator guard and check whether the eccentric blocks are rotating outward.

3) Replace any two phase lines of the power supply of the electric control box, sprinkle some sand on the screen, and the one with the faster sand discharge speed is the correct direction.

3. The screen is not tightly fitted to the screen frame, and the poor quality of the screen.

After the rubber strip supporting the screen is worn, the screen cannot reliably contact it; The screen is not properly tightened.

The screen generally has an upper screening layer and a lower stress layer, and the two layers are required to fit tightly. If the pre-tensioning process of the screen is poor, when the stress layer at the bottom of the screen is tightened, the screening layer is not tightened, and the throwing force of the material is greatly reduced during operation, and it cannot be screened and discharged smoothly.

Solution

Replace a high-quality screen.