Compared with Ball Mill, what are the Advantages of Vertical Mill?

Date:2024-10-17Ball mill, everyone must be familiar with it. As a large-scale mining grinding mill, it is widely used in various industries due to its low price and high capacity. However, according to the development trend of the powder industry, the high-efficiency, energy-saving and eco-friendly vertical mill has powerful performance advantages among various types of grinding equipment.

1. Structure and installation

Vertical mill has a simple structure, which is installed vertically, occupying a small area with simple infrastructure, and installed easily in a short time. Ball mill has a more complex structure and is installed horizontally, which is technically difficult to install, has high requirements for the foundation, takes a long time, and occupies a large area. Both can be arranged outdoors, but generally speaking, the construction area of the vertical mill is 70% of that of the ball mill, and the building space is 50%-60% of that of the ball mill, with a low investment cost.

2. Crushing method

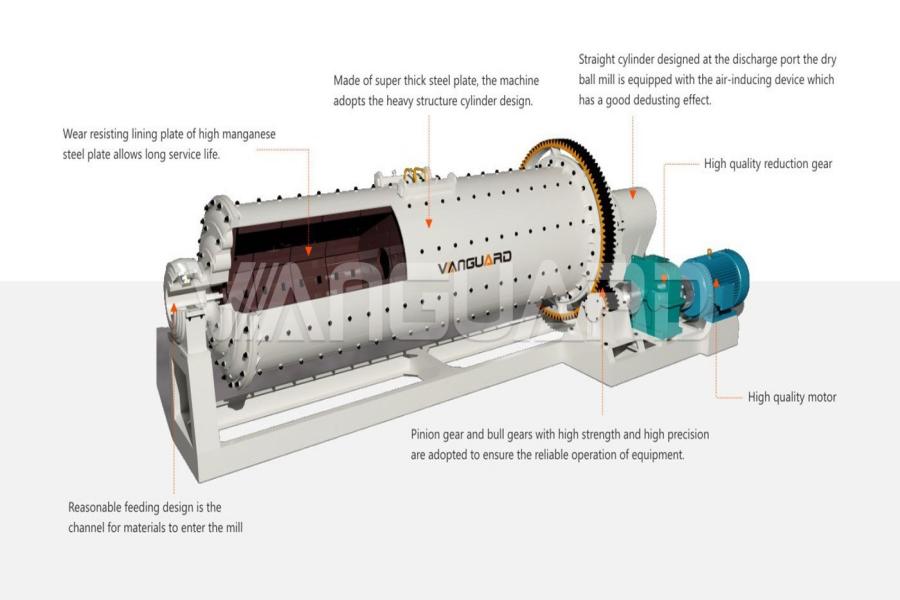

Vertical mill mainly adopts the grinding crushing method, followed by impact force, which is suitable for fine grinding and ultrafine grinding, with low grinding medium consumption and long liner service life. Ball mill mainly adopts impact crushing method, followed by grinding, which is suitable for coarse grinding and fine grinding, with high grinding medium consumption and short lining service life.

3. Process flow

Vertical mill integrates crushing, drying, grinding, classifying and transportation. Compared with the ball mill, the vertical mill has a simple process flow, small capital investment, and can save a dryer for the mill system. In addition, the vertical mill has a separator that uses hot flue gas to transport materials and does not require a powder selector and elevator, and the dusty gas out of the vertical mill is directly collected by the powder collector. Therefore, the vertical mill system has a simple process, low failure rate, high operation rate, and compact layout.

Generally speaking, for finished products of the same fineness, the vertical mill process is adopted, and after two stages of grinding, the product fineness can reach the required level, while the traditional ball mill process requires three stages of grinding.

4. Energy consumption

The vertical mill has fewer moving parts with low energy consumption and less vibration; The ball mill has all parts in motion with a high energy consumption and greater vibration. In addition, the vertical mill uses grinding rollers to directly grind materials on the grinding disc, which saves 30% to 40% of energy compared to ball mill systems.

Generally speaking, when the raw material grindability and product particle size are the same, the power consumption of vertical mills can be reduced by 30% to 50% compared to ball mills.

5. Drying capacity

The vertical mill combines grinding, classifying and drying (when the material has a high moisture content) in one machine. The hot air flow is used to convey materials. When grinding materials with relatively high moisture content (such as coal, slag, etc.), the air inlet temperature can be controlled to make the product reach the final moisture content. The vertical mill can dry materials with a moisture content of 12%-15%, and has a strong drying capacity. Even the drying ball mill can only dry materials with a moisture content of 3%-4%. Therefore, the vertical mill used in the production of materials with high moisture content not only saves economic costs but also saves time costs.

6. Material discharge method

The material discharge from the vertical mill is forced, which can avoid over-grinding. After the material is rolled by the grinding roller on the grinding disc, it is carried away by the high-speed airflow of the wind ring at the edge of the grinding disc. The qualified fine powder is collected by the dust collector along with the airflow through the powder selector.

The material discharged from the ball mill is self-discharged, which is prone to over-grinding, especially the overflow type ball mill, whose material overflows automatically. When the material level is higher than the discharge port, the material is automatically discharged, which consumes energy and is prone to over-grinding.

7. Product quality

1) Compared with the ball mill, the vertical mill has a higher degree of homogenization and purity. When the vertical mill working, the finished powder classification takes a short time to avoid over-grinding.

2) Due to the unique working principle, there is no direct contact between metals during the operation of the vertical mill, so there is little metal wear and small pollution to the finished material.

3) It is very convenient to adjust the separator speed, wind speed and grinding roller pressure of the vertical mill, and the product fineness can be adjusted conveniently. The built-in powder selection device can remove fine powder in time to reduce over-grinding and get a stable product particle composition. The ball mill is prone to over-grinding. The unit wear of limestone is generally 4-6 grams/ton, and the ball mill is as high as 500 grams/ton.

4) When the vertical mill grinds white minerals, the impact on its whiteness is much smaller than that of the ball mill.

8. Environmental impact

1) The vertical mill has a soft sound during operation, generally around 80 decibels. The grinding roller and the grinding disc are not in direct contact (devices are installed to prevent direct contact to avoid destructive impact and severe vibration), and the noise is about 20-25 decibels lower than the ball mill.

2) The vertical mill adopts an integral seal, the system operates under negative pressure with less dust and a clean environment. The ball mill is open with a dust problems.

9. Development and application

Vertical mill manufacturing technology started late, and its industrial production application is in the promotion stage; The ball mill manufacturing technology is relatively mature and has been widely used in industrial production. However, in the future, as vertical mill technology becomes more mature and efficient and eco-friendly equipment becomes more widely used, its application scope will be more extensive.

10. Price and capacity

There is a reason why the ball mill is popular. Among large-scale grinding production equipment, the ball mill is relatively cheap with a small one-time investment, high capacity, wide application range and simple operation. Vertical mills do not have an advantage in price, but they are equipped with hydraulic systems, which make maintenance and operation convenient and fast.

As a high-efficiency and energy-saving grinding equipment, the vertical mill is gradually applied to slag grinding, cement clinker grinding, power plant desulfurization, phosphate rock grinding, manganese ore grinding and many other industries due to their excellent performance, becoming the preferred grinding equipment for energy conservation, emission reduction and eco-friendly. TToday, with increasingly stringent eco-friendly requirements, the vertical mill has become the preferred equipment for raw material grinding and coal grinding in the world.