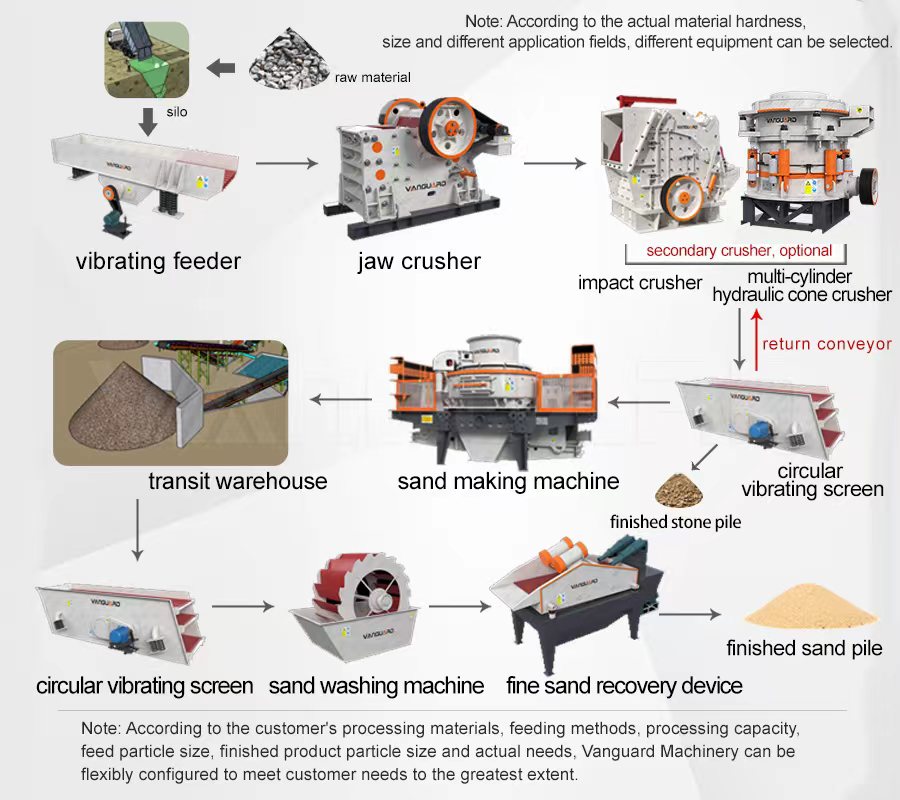

Process Flow of 1000 t/h Dry Sand Making and Crushing Production Line

Date:2024-11-14A 1000 t/h dry sand making and crushing production line typically involves several stages, from raw material feeding to final product delivery. The process aims to crush and refine sand and aggregates for use in construction, concrete mixing, road building, or other applications. Below is a detailed process flow for such a production line:

1. Feeding

Raw material: Usually, this comes from a quarry, riverbed, or other natural sources and consists of rocks, gravel, or other aggregates.

Feeding system: A vibrating feeder or hopper is used to feed raw materials into the primary crusher. The material is evenly distributed, and the size of the material may be pre-screened.

2. Primary Crushing

Primary crusher: The raw material is first crushed by a jaw crusher. The purpose is to break down large rocks into smaller sizes (typically 150–300 mm).

Output size: This produces a coarser fraction that will be further processed.

3. Secondary Crushing

Secondary crusher: After the primary crushing, the material goes to a cone crusher, impact crusher, or hammer crusher for further reduction in size.

Output size: The material is reduced to a smaller, more uniform size, generally between 40-100 mm.

4. Screening

Vibrating screens: After secondary crushing, the material is screened to separate fine particles from larger ones.

Screening sizes: The oversize material (larger than the desired size) goes back to the crusher for further reduction, while the fine material (sand) moves forward in the process.

Separation of fine particles: This process ensures that finer sand (usually in the range of 0-5 mm) is separated from larger aggregates.

5. Dry Sand Making (Artificial Sand Production)

Vertical shaft impact crusher (VSI) or sand maker: For dry sand making, a VSI crusher is commonly used to further crush and shape the material, converting it into fine sand with the desired grain shape and size (typically 0-5 mm). The VSI crusher works by throwing the material against a hard surface at high speed, which causes the material to break and reshape into fine particles.

Output: The VSI machine produces cubical, well-graded sand ideal for construction purposes.

6. Stockpiling & Storage

Finished product stockpile: After final crushing and shaping, the product is typically conveyed to stockpiles using belt conveyors. The material is separated by different grades: fine sand, coarse sand, and aggregate.

Storage: The sand and aggregates are stored separately or mixed, depending on customer specifications.

Summary of the Process Flow:

Raw Material Feeding → 2. Primary Crushing → 3. Secondary Crushing → 4. Screening → 5. Dry Sand Making (VSI) → 6. Stockpiling & Storage

This dry sand production line is designed to produce high-quality sand with minimal water usage, making it ideal for areas where water resources are limited or when environmental considerations require dry processing.